Industry information

Company News

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Surface treatment methods for aluminum veneer and their advantages and disadvantages comparison

- New Vision of Aluminum Veneer: Infinite Possibilities of Lightweight Materials

- Aluminum veneer: the 'invisible star' of the construction industry

- Hyperbolic aluminum veneer: the "mirror dancer" of modern architecture

Industry dynamics

- Irregular aluminum veneer: perfect integration of creativity and craftsmanship

- Fluorocarbon aluminum veneer, the new darling of the construction industry!

- Aluminum veneer customization, creating a new trend of personalized space

- What is the thermal expansion and contraction performance of curtain wall aluminum veneer?

- Shocked! Aluminum veneer has stunning colors that you must have never seen before!

Frequently asked questions

- How to check the quality of aluminum veneer?

- What environmental issues should be paid attention to in the production and use of aluminum veneer?

- What is the development prospect of aluminum veneer?

- What occasions is aluminum veneer suitable for?

- What are the advantages of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Cutting and processing technology for 2.5mm aluminum veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: 2022-03-12 04:01:24

- Click:0

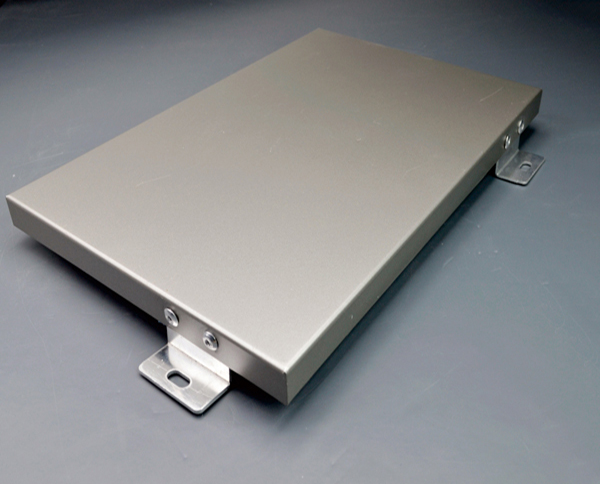

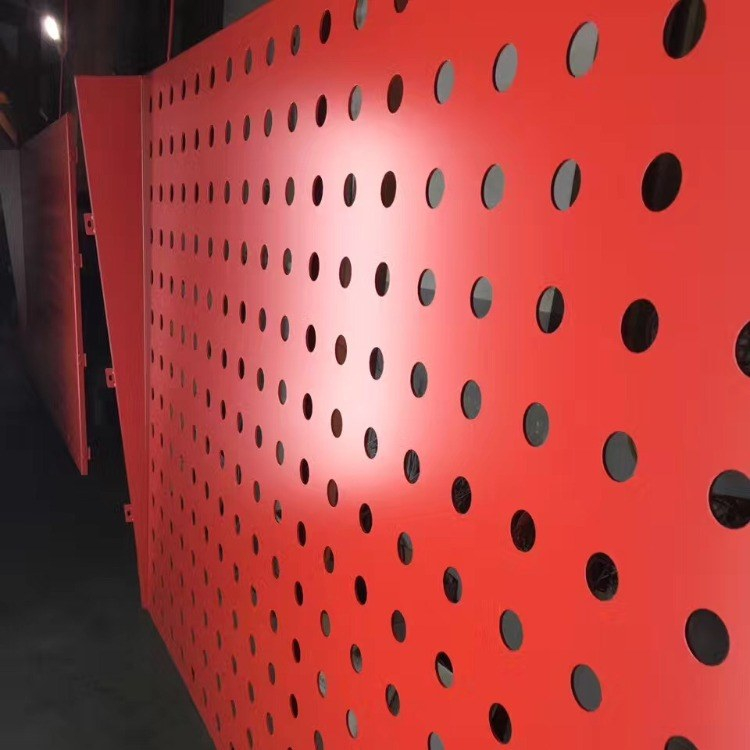

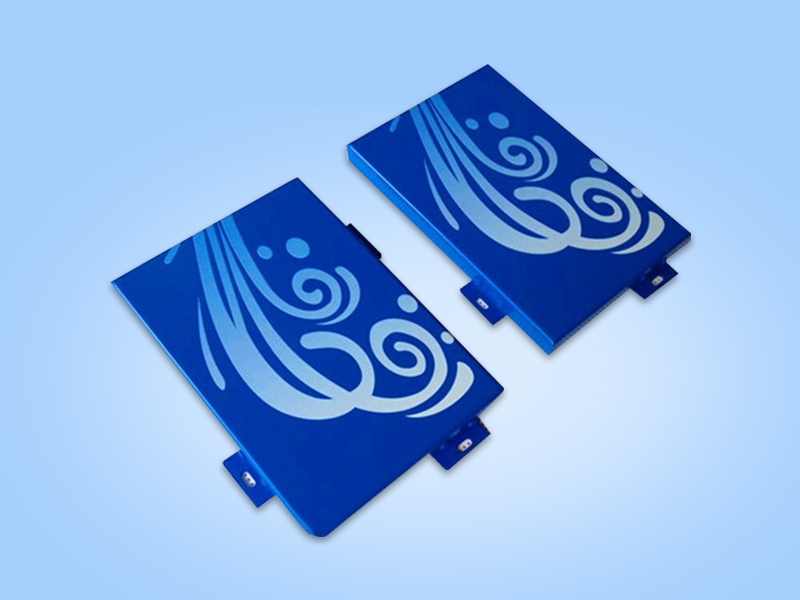

Aluminum veneer, as a lightweight and weather resistant building material, has a wide range of applications in architectural decoration. And 2.5mm thick aluminum veneer is a common specification, and its cutting and processing technology is also an important factor affecting its application effect. The following will provide a detailed introduction to the cutting and processing technology of 2.5mm thick aluminum veneer.

1、 Selection of cutting tools

Cutting 2.5mm thick aluminum veneer requires selecting suitable cutting tools, commonly used cutting tools include saw blades, scissors, punching machines, etc. Saw blades are one of the more common cutting tools, and different models of saw blades can be selected for cutting according to different aluminum veneer materials and thicknesses.

2、 Cutting process flow

1. Preparation work: Firstly, the aluminum veneer needs to be surface treated, including removing burrs, oil stains, and other debris to ensure cutting quality and surface aesthetics.

2. Positioning: Before cutting, the aluminum veneer needs to be positioned to determine the cutting position and angle, in order to avoid deviation and material waste.

3. Cutting: Use appropriate cutting tools for cutting, and single or multiple knives can be used simultaneously as needed for cutting. During the cutting process, it is important to maintain stable gestures and appropriate feed rates to avoid deviations and damage to the surface of the aluminum veneer.

4. Trimming: After cutting, the aluminum veneer needs to be trimmed, including removing excess material, polishing edges, etc., to achieve a smooth and even effect.

3、 Precautions

During the cutting process of 2.5mm thick aluminum veneer, the following points should be noted:

1. Operators need to possess certain skills and experience to ensure cutting quality and safety.

2. Cutting tools need to be kept sharp and clean to avoid issues such as wear and blockage.

During the cutting process, it is important to maintain a stable and uniform speed to avoid deviations and damage to the surface of the aluminum veneer.

After cutting, it is necessary to inspect and repair the aluminum veneer to ensure cutting quality and surface aesthetics.

4、 Summary

The cutting and processing technology of 2.5mm thick aluminum veneer is one of the important factors affecting its application effect. When performing cutting and processing, it is necessary to pay attention to selecting suitable cutting tools, following the correct process flow, ensuring safe operation, and keeping the tools clean to ensure cutting quality and surface aesthetics.

Customer service QQ

Customer service QQ