Industry information

Company News

- Fluorocarbon aluminum veneer, the "invisible Iron Man" of modern architecture!

- Hyperbolic aluminum veneer: the beauty of curves in modern architecture

- Fluorocarbon aluminum veneer: the new darling of modern architecture!

- Aluminum veneer customization, creating a new trend of personalized space

- Fluorocarbon aluminum veneer, creating a "green coat" for modern architecture

Industry dynamics

- Aluminum veneer: the fashionable 'Green Man' in architecture

- Brand building and marketing of aluminum veneer

- Hyperbolic aluminum veneer: a magnificent transformation of aluminum art

- Hyperbolic aluminum veneer: the fashionable choice for modern architecture?

- Beautiful and durable special-shaped roller coated aluminum veneer products

Frequently asked questions

- How to check the quality of aluminum veneer?

- What are the special points to pay attention to when installing aluminum veneer?

- What are the surface treatment methods for aluminum veneer?

- What is the development prospect of aluminum veneer?

- What is the production process of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Introduction to the material and process of column wrapped wood grain aluminum veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: 2022-03-15 16:28:59

- Click:0

The column wood grain aluminum veneer is a type of veneer made of aluminum alloy material, and its surface is treated with special technology to form a wood like texture effect. This material comes in a variety of colors, and different colors and patterns can be selected according to needs to meet different decorative needs. This article will provide a detailed introduction to the material and process of column wrapped wood grain aluminum veneer.

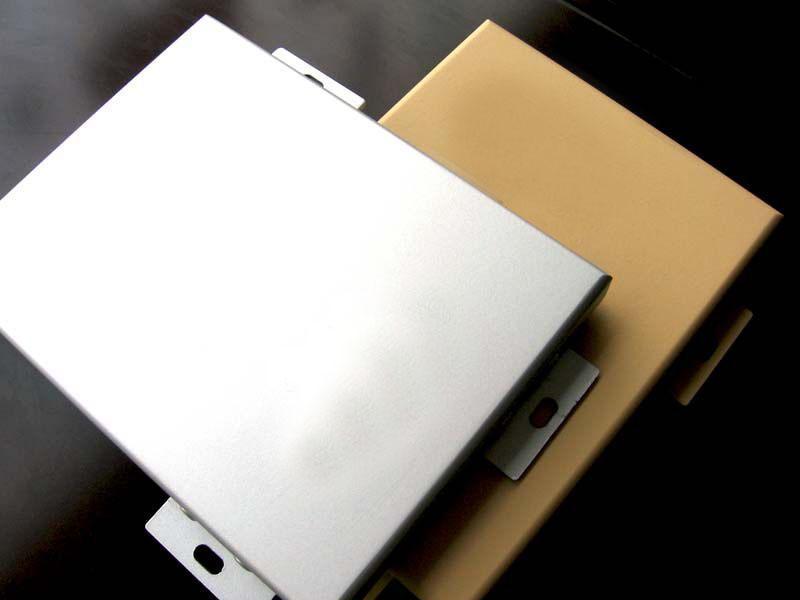

Let's take a look at the material of the column wrapped wood grain aluminum veneer. The main raw material of column wood grain aluminum veneer is aluminum alloy, which is a lightweight, corrosion-resistant, and high-strength metal material. Aluminum alloy has good plasticity and processability, and can be made into various shapes and sizes of veneers. In order to enhance the decorative effect of the column wrapped wood grain aluminum veneer, special pigments and coatings such as fluorocarbon paint and polyester powder are usually added.

Next, let's take a look at the process of wrapping column wood grain aluminum veneer. The production process of column wrapped wood grain aluminum veneer mainly includes the following steps:

1. Cutting of aluminum alloy sheet: It is necessary to cut the aluminum alloy sheet into the required size and shape according to the design requirements.

2. Surface treatment: Surface treatment of the cut aluminum alloy sheet, including grinding, cleaning, removal of oxide film, etc.

3. Coating: Next, the processed aluminum alloy sheet is coated, including primer, topcoat, etc. The painting process requires strict control of temperature and humidity to ensure the quality and stability of the coating.

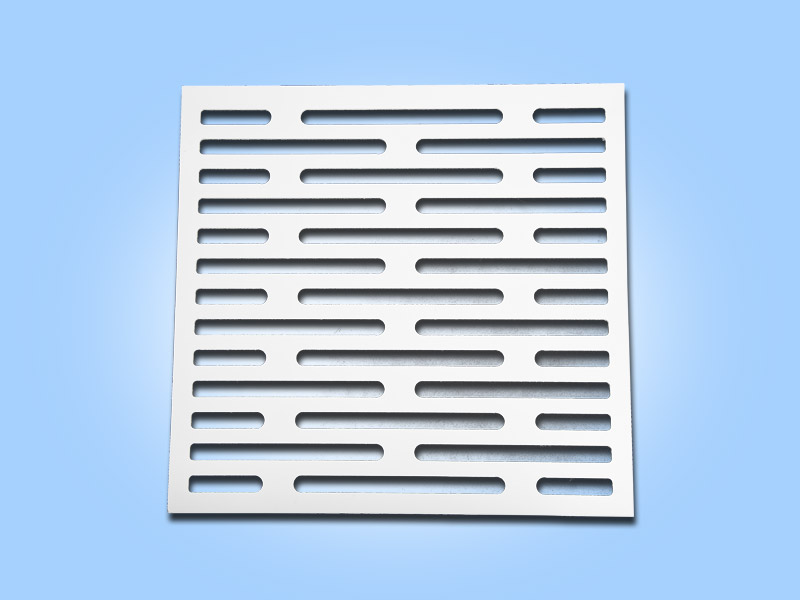

4. Printing: Print the coated aluminum alloy sheet to form the desired wood grain pattern. The printing process requires the use of professional printing equipment and technology to ensure the clarity and accuracy of the patterns.

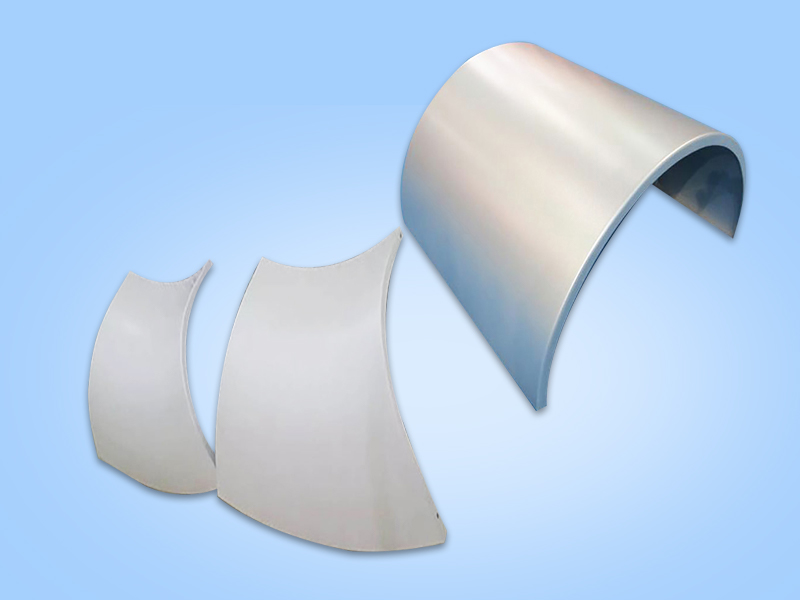

5. Composite: The printed aluminum alloy sheet is combined with plastic film to form a column wrapped wood grain aluminum veneer. The process of composite requires controlling temperature and pressure to ensure the quality and stability of the composite material.

The wood grain aluminum veneer with wrapped columns has become an indispensable part of modern architectural decoration due to its unique design and excellent performance. The choice of material and craftsmanship directly affects the decorative effect and service life of the product. Through scientific management and rational use, we can fully leverage the advantages of column wrapped wood grain aluminum veneer, improving the aesthetics and comfort of buildings.

Customer service QQ

Customer service QQ