Industry information

Company News

- Explore the magical world of hyperbolic aluminum veneer

- Aluminum veneer: understated luxury in architecture

- Aluminum veneer: the beauty of architecture, the choice of materials

- How much do you know about aluminum veneer: a fashionable choice for modern architecture?

- The secret behind aluminum veneer: the perfect combination of lightness and durability

Industry dynamics

- Aluminum veneer: a fashionable outerwear for industrial buildings

- The secret to cleaning aluminum veneer: Say goodbye to stains and troubles!

- Pay attention to the social responsibility of aluminum veneer manufacturers

- Customized aluminum veneer, creating a new trend of personalized space

- Aluminum veneer curtain wall, the fashionable outerwear of modern architecture

Frequently asked questions

- What is the development prospect of aluminum veneer?

- What is the approximate price of aluminum veneer?

- How to check the quality of aluminum veneer?

- What are the advantages of aluminum veneer?

- What occasions is aluminum veneer suitable for?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What are the processing techniques for curtain wall aluminum veneer?

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: February 28, 2025 17:14:57

- Click:0

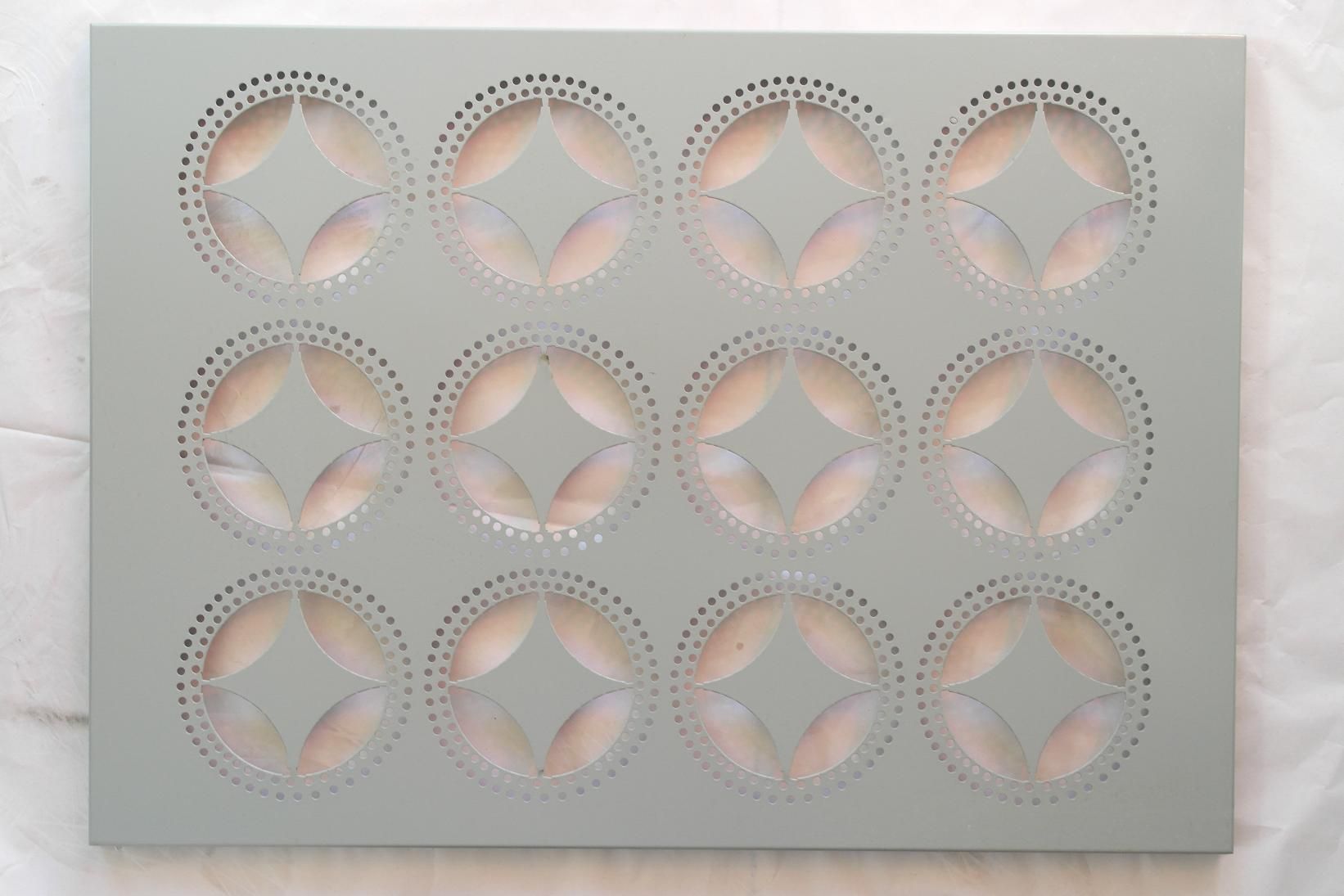

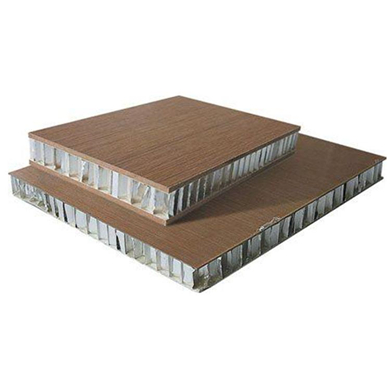

Curtain wall aluminum veneer is a common decorative material for building exterior walls, which has the advantages of lightweight, corrosion resistance, and easy cleaning. The processing technology of curtain wall aluminum veneer has a significant impact on its quality and appearance. This article will provide a detailed introduction to the processing technology of curtain wall aluminum veneer from the aspects of raw material procurement, cutting, bending, slotting, etc.

1、 Raw material procurement

The main raw material for curtain wall aluminum veneer is aluminum alloy sheet, and its quality directly affects the quality of the entire curtain wall aluminum veneer. When purchasing raw materials, the following points should be noted:

1. Choose high-quality aluminum alloy sheet suppliers to ensure that the purchased raw materials meet national standards and quality requirements.

2. For curtain wall aluminum panels of different specifications and sizes, customized procurement should be carried out according to actual needs to avoid waste and cost increase.

3. During the procurement process, attention should be paid to the surface quality and thickness of raw materials to ensure that they meet the design requirements and service life requirements.

2、 Cutting

Cutting is one of the important processes in the processing of aluminum veneer for curtain walls, and its accuracy and efficiency directly affect the effectiveness of subsequent processes. Generally speaking, the cutting of curtain wall aluminum veneer is carried out using CNC machine tools or shearing machines, which can achieve high-precision and high-efficiency cutting. During the cutting process, the following points should be noted:

For curtain wall aluminum panels of different specifications and sizes, precise measurement and calculation are required to ensure the accuracy and precision of cutting.

2. During the cutting process, attention should be paid to protecting the surface of the aluminum alloy sheet to avoid scratches and oxidation.

3. Quality inspection and size adjustment are required after cutting to ensure the accuracy and precision of the cutting.

3、 Bending

Bending is one of the more complex processes in the processing of aluminum veneer for curtain walls, which requires certain skills and experience. Generally speaking, the bending of aluminum veneer for curtain walls is carried out using CNC bending machines, which can achieve high-precision and high-efficiency bending. During the bending process, the following points should be noted:

For curtain wall aluminum panels of different specifications and sizes, precise measurement and calculation are required to ensure the accuracy and precision of bending.

2. During the bending process, it is necessary to pay attention to protecting the surface of the aluminum alloy sheet to avoid problems such as scratches and oxidation.

3. After the bending is completed, quality inspection and size adjustment are required to ensure the accuracy and precision of the bending.

4、 Slotting

Slotting is the final process in the processing of aluminum veneer for curtain walls, and its main function is to provide convenience for subsequent installation. Generally speaking, the slotting of curtain wall aluminum veneer is processed using a CNC slotting machine, which can achieve high-precision and high-efficiency slotting. During the slotting process, the following points should be noted:

For curtain wall aluminum panels of different specifications and sizes, precise measurement and calculation are required to ensure the accuracy and precision of slotting.

2. During the slotting process, attention should be paid to protecting the surface of the aluminum alloy sheet to avoid scratches and oxidation.

3. After the slotting is completed, quality inspection and size adjustment are required to ensure the accuracy and precision of the slotting.

The processing technology of curtain wall aluminum veneer includes raw material procurement, cutting, bending, slotting, and other aspects, all of which require certain skills and experience. Customers should pay attention to their processing technology and technical level when choosing curtain wall aluminum veneer suppliers to ensure that the quality and performance of the selected products meet the standard requirements.

Customer service QQ

Customer service QQ