Industry information

Company News

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Fluorocarbon aluminum veneer: the new favorite of "light luxury" in the construction industry

- Fluorocarbon aluminum veneer: the fashionable choice for modern architecture?

- Customize aluminum veneer to create a unique and personalized space!

Industry dynamics

- Irregular aluminum veneer: Innovative building materials, shaping the beauty of future architecture

- Production and Sustainable Development of Aluminum Veneer

- Decorative performance perforated aluminum veneer

- Key points for installing indoor aluminum veneer curtain walls to ensure building safety

- Customize aluminum veneer to create a unique spatial aesthetic

Frequently asked questions

- How to check the quality of aluminum veneer?

- What occasions is aluminum veneer suitable for?

- What are the advantages of aluminum veneer?

- How to choose and purchase aluminum veneer?

- What is the production process of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

The secret behind aluminum veneer: the craftsmanship wisdom behind its lightness

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: February 21, 2025 05:11:44

- Click:0

Have you ever thought about what kind of craftsmanship wisdom is hidden behind those seemingly ordinary aluminum veneers? I'm here today to uncover the story behind this.

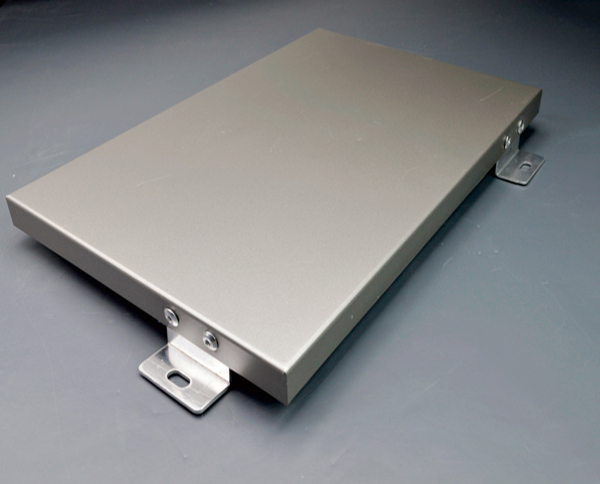

It has to be said how "lightweight" aluminum veneer is. Imagine how heavy the exterior walls of those skyscrapers would be if they were all made of bricks, tiles, and stones! Using aluminum veneer is much easier, lightweight, durable, and environmentally friendly, it is simply the "little freshness" of the building materials industry.

I remember once I visited a production workshop for aluminum veneer, and the scene was simply breathtaking. Rows of huge machines are working tirelessly, pressing aluminum plates into various shapes. This process is simply a visual and auditory feast!

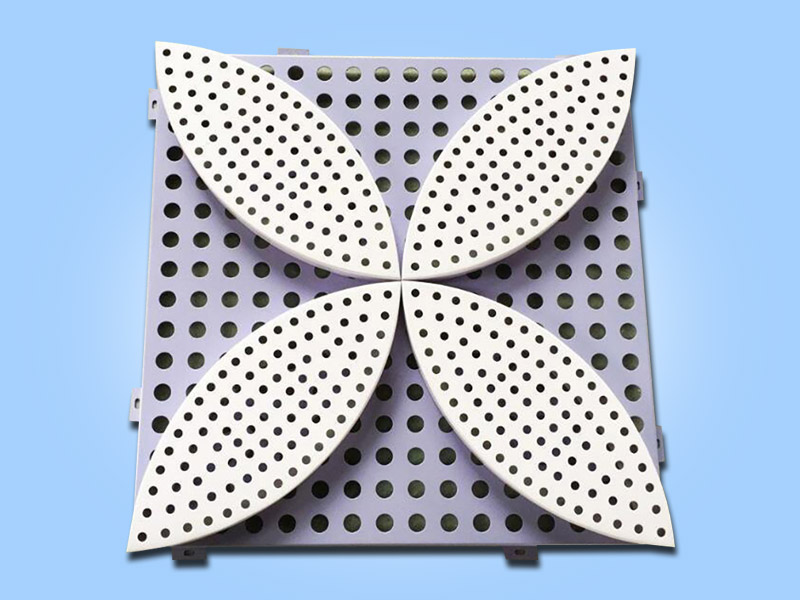

It's the 'embossing' stage. I watched as those aluminum plates were squeezed by the embossing machine, instantly becoming colorful, as if they had been enchanted. This process not only enriches the appearance of aluminum veneer, but also increases its strength and corrosion resistance. Just like the clothes we usually wear, those with patterns are easier to resist sandstorms.

Next is the process of "baking paint". I stood there, watching rows of aluminum plates being baked at high temperatures in the baking oven of the paint booth, and then coated with a thick layer of paint. This layer of paint not only looks beautiful, but also prevents aluminum veneer from rusting and extends its service life. It's like putting "armor" on aluminum veneer, allowing it to stand firm in wind and rain.

Next is the 'bending' stage. Although this process is simple, it is also the key to testing the craftsmanship. Under the control of the machine, aluminum plates are precisely bent into various shapes, like magic. This process requires precise craftsmanship and rich experience.

The most impressive part for me is the "welding" process. During the welding process, workers need to weld the holes on the aluminum veneer to ensure overall sealing. This process requires extremely high precision and stability, and even a small mistake can cause the entire aluminum veneer to be scrapped.

In addition to these, there are many other stages in the production process of aluminum veneer, such as cutting, polishing, assembly, and so on. Every step requires workers to work hard to create the perfect aluminum veneer.

Speaking of which, I think of my friend's community, where the exterior walls of that building are made of aluminum veneer. Every day when I go home, I stand downstairs and look up at that building, imagining how those aluminum veneers have gradually gone from raw materials to what they are now.

There are such "aluminum veneers" everywhere in life. The computer cases we commonly use are also made of aluminum veneer. Think about it, without those precise craftsmanship and the hard work of countless skilled workers, how could we enjoy such a convenient life?

Next time you see those ordinary aluminum veneers, you may want to pay more attention to the stories behind them. Those seemingly ordinary items actually contain the crystallization of human wisdom.

You know what? The application field of aluminum veneer is not limited to the construction industry. It is also widely used in aviation, automotive, furniture and other fields. The planes we usually fly on have many components made of aluminum veneer. This is not only because aluminum veneer is lightweight, but also because it has excellent high temperature resistance and corrosion resistance.

With the development of technology, the process of aluminum veneer is also constantly improving. Nowadays, many aluminum veneers are produced using CNC technology, greatly improving production efficiency and product quality. This is like working on a computer in our daily lives, which has increased efficiency by countless times compared to traditional manual operations.

Although aluminum veneer is common in our daily lives, the craftsmanship behind it should not be underestimated. It is not only a building material, but also a symbol of culture and spirit. Let us give a thumbs up to those workers who silently contribute, and let us cherish the seemingly ordinary items around us even more. Because behind them, there are unknown secrets and stories.

Customer service QQ

Customer service QQ