Frequently asked questions

Company News

- Fluorocarbon aluminum veneer: the "fashionable coat" of modern architecture

- Aluminum veneer customization, creating personalized spatial aesthetics

- Exploring "Irregular Aluminum Veneer": The New Creative Favorite in the Aluminum Industry

- Fluorocarbon aluminum veneer: the "fashionista" in the aluminum industry

- Fluorocarbon aluminum veneer: the 'wizard' of architectural aesthetics

Industry dynamics

- What is the thermal expansion and contraction performance of curtain wall aluminum veneer?

- Aluminum veneer curtain wall: Unveiling the "coat" of modern architecture

- Manufacturing process and engineering application of 2.5mm ceiling aluminum veneer

- Unique design of 2.0mm aluminum veneer highlights individual charm

- The secret to cleaning aluminum veneer: Say goodbye to stains and troubles!

Frequently asked questions

- What is the development prospect of aluminum veneer?

- What is the production process of aluminum veneer?

- How to check the quality of aluminum veneer?

- What is the approximate price of aluminum veneer?

- What are the surface treatment methods for aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What is the production process of aluminum veneer?

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: March 2, 2025 13:44:26

- Click:0

What is the production process of aluminum veneer?

Aluminum veneer is a commonly used building decoration material, which has the characteristics of good weather resistance, easy processing, and light weight, and has been widely used in the construction industry. So, how is aluminum veneer produced? Below, we will provide a detailed explanation from four aspects: raw material preparation, processing and manufacturing, coating treatment, and quality inspection.

1、 Raw material preparation

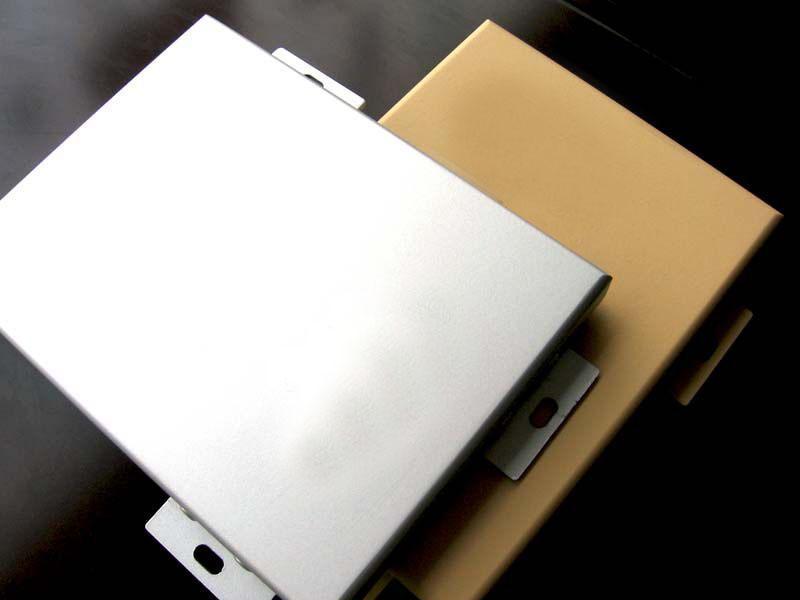

1. Material selection: High quality aluminum alloys are used as raw materials, commonly including aluminum alloys 3003, 5005, etc. These aluminum alloys have good corrosion resistance and strength, making them suitable for outdoor decoration.

2. Material processing: Cut and saw the selected aluminum alloy sheet to obtain the required sheet size and shape.

3. Surface treatment: Surface treatment of aluminum alloy plates through sandblasting, polishing, and other methods to improve their roughness and prepare for subsequent coating treatments.

2、 Processing and manufacturing

1. Cutting: Cut the surface treated aluminum alloy plate according to the design requirements to obtain the required size of aluminum veneer.

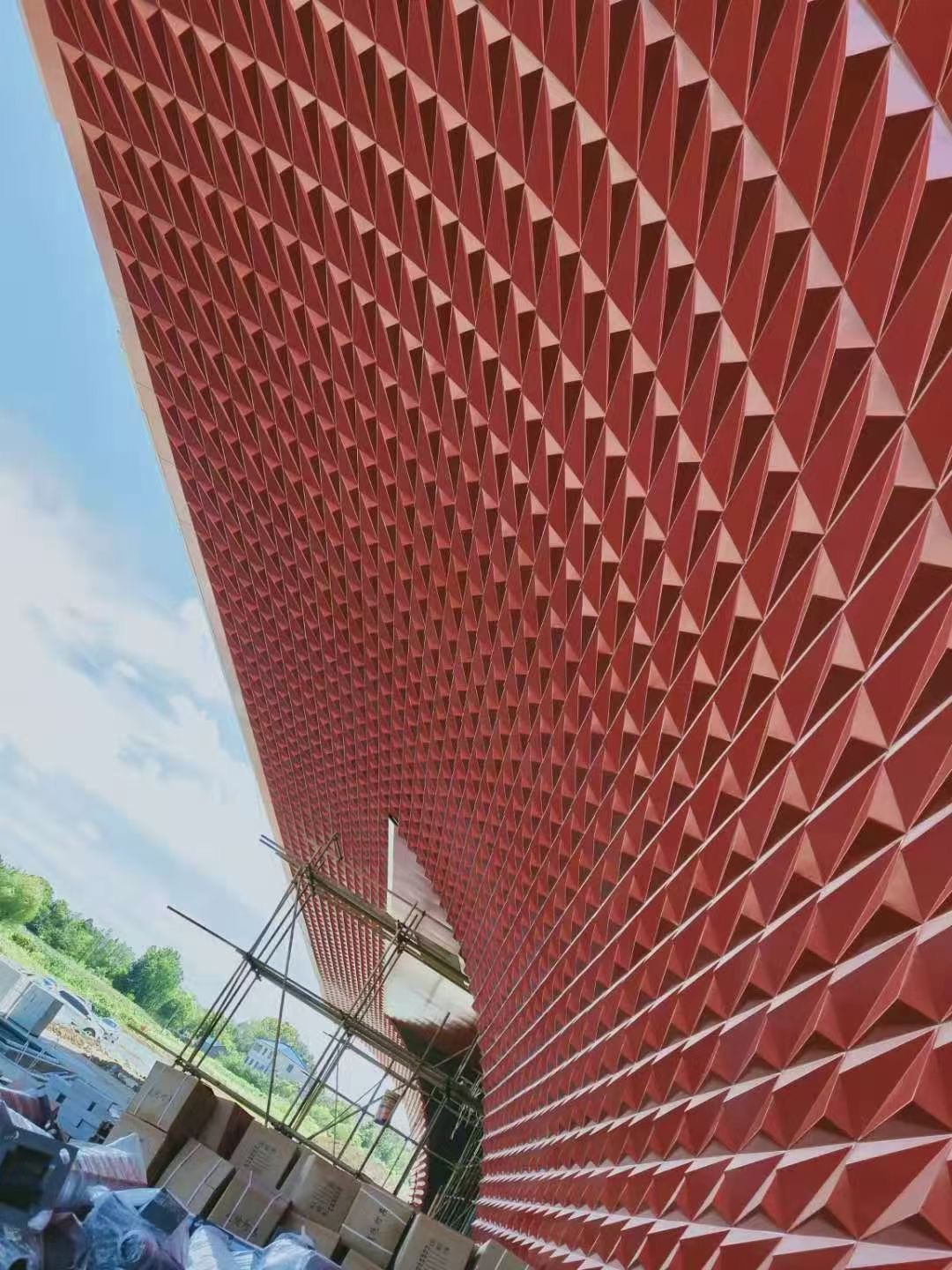

2. Bending: Use a professional bending machine to bend aluminum veneer into different shapes of components, such as flat panels, vertical panels, etc.

3. Forming: Stamping or mechanically forming the bent aluminum veneer into various required shapes and sizes.

3、 Painting treatment

1. Acid washing and deoxygenation: Soak aluminum veneer in an acidic solution to remove surface oxides, making it easier for the surface to adhere to the coating.

2. Primer coating: Spray a layer of primer to enhance the adhesion and weather resistance of the coating.

3. Topcoat coating: According to design requirements, multiple coats of topcoat are sprayed to form coatings of different colors and effects.

4、 Quality inspection process

1. Appearance quality inspection: Conduct a visual inspection of the coated aluminum veneer to ensure that the coating is uniform and the color meets the requirements.

2. Functional testing: Testing the strength, weather resistance, and other functions of aluminum veneer to ensure compliance with relevant standards.

3. Packaging for factory delivery: Aluminum veneer that has passed quality inspection is packaged and labeled with relevant information to prepare for factory delivery.

5、 Summary:

Through the above description, we can clearly understand the production process of aluminum veneer. Starting from the preparation of raw materials, through processing and manufacturing, painting treatment, and quality inspection, the final product of aluminum veneer has excellent appearance and functional performance, which can meet the needs of building decoration. In the future development, with the advancement and innovation of technology, the production process of aluminum veneer will continue to improve, providing more high-quality products for the construction industry.

- previous page:What are the advantages of aluminum veneer?

- Next page:What occasions is aluminum veneer suitable for?

Customer service QQ

Customer service QQ