Industry information

Company News

- The secret behind aluminum veneer: the technological charm behind its lightness

- Hyperbolic aluminum veneer, creating a new style of modern architecture!

- Aluminum veneer customization, creating a new trend of personalized space

- The Charm of Aluminum Veneer: The 'Hidden Hero' of Modern Architecture

- Fluorocarbon aluminum veneer: the new favorite of aluminum materials, a new chapter in architectural aesthetics

Industry dynamics

- Comprehensive analysis of the performance advantages of aluminum veneer!

- Light luxury choice 1.5mm aluminum veneer exterior wall decoration

- How about the aging resistance of aluminum veneer?

- The Fashion Journey of Hyperbolic Aluminum Veneer: From Modern to Future

- Irregular aluminum veneer: Reshaping a new height in architectural aesthetics

Frequently asked questions

- What is the development prospect of aluminum veneer?

- How to check the quality of aluminum veneer?

- What occasions is aluminum veneer suitable for?

- What is the approximate price of aluminum veneer?

- What are the special points to pay attention to when installing aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What are the specifications and standards for punched aluminum veneer?

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: February 20, 2025 21:01:33

- Click:0

Punched aluminum veneer, as a widely used material in fields such as architectural decoration, billboards, curtain walls, etc., its specification standards are also a very important aspect. The following will introduce the specifications and standards of punched aluminum veneer from the following aspects.

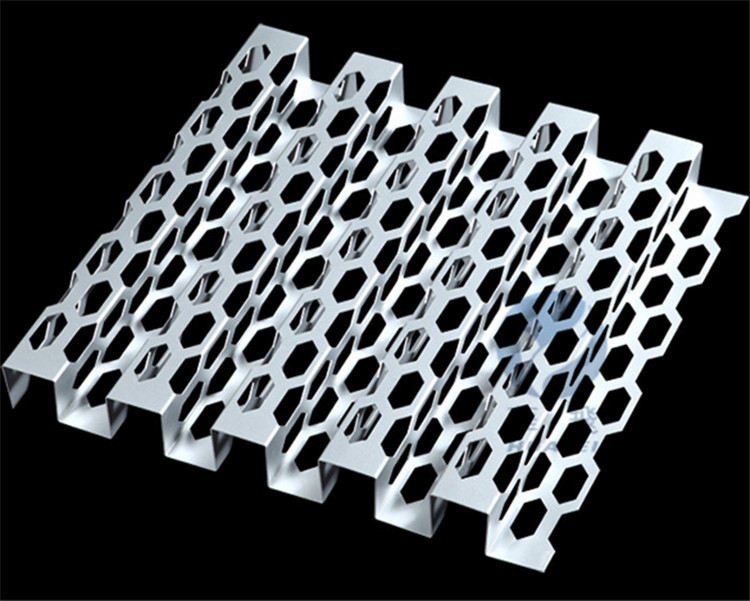

1. Thickness

The thickness of punched aluminum veneer is one of its most basic specification standards. Generally speaking, the thickness range of punched aluminum veneer is between 0.6mm-3mm, and punched aluminum veneer of different thicknesses is suitable for different occasions and needs. For example, in indoor decoration, thinner perforated aluminum veneer can be chosen to increase indoor air circulation and lighting; In outdoor buildings, thicker punched aluminum veneers can be chosen to increase their weather resistance and wind pressure resistance.

1. Length and width dimensions

The length and width dimensions of punched aluminum veneer are also one of its important specification standards. Generally speaking, the length and width dimensions of punched aluminum veneer can be customized according to actual needs, with common sizes including 1200mm, 2400mm, 1500mm, 3000mm, etc. The aspect ratio of punched aluminum veneer also needs to be adjusted according to the actual situation to meet design requirements and usage effects.

1. Aperture size

The aperture size of punched aluminum veneer is also one of its important specification standards. Generally speaking, the aperture size of punched aluminum veneer can be selected according to actual needs, and common aperture sizes include 3mm, 5mm, 8mm, etc. The size of the aperture also affects factors such as breathability and transparency of punched aluminum veneer, so it needs to be comprehensively considered and selected according to the actual situation.

1. Surface treatment

The surface treatment of punched aluminum veneer is also one of its important specification standards. Generally speaking, the surface treatment of punched aluminum veneer includes various processes such as anodizing, spraying, electrophoretic coating, etc. Each process has its own advantages, disadvantages, and applicable scope. When choosing perforated aluminum veneer, it is necessary to consider and select comprehensively based on actual needs and budget factors.

The specification standards for punched aluminum veneer are a comprehensive issue that requires consideration and improvement from multiple aspects such as thickness, length and width dimensions, aperture size, and surface treatment. Only through continuous optimization and improvement of specifications, standards, and technical means can punched aluminum veneer products that better meet demand and aesthetic requirements be produced.

Customer service QQ

Customer service QQ