Frequently asked questions

Company News

- Qimei hyperbolic aluminum veneer: the fashionable new favorite of architecture

- Aluminum veneer curtain wall, perfect integration of architectural aesthetics and technology

- Hyperbolic aluminum veneer: an innovative choice in architectural aesthetics

- Aluminum veneer: the charm of metal in modern architecture

- Fluorocarbon aluminum veneer: the "invisible fighter" of modern architecture

Industry dynamics

- Fluorocarbon aluminum veneer: the fashionable choice for modern architecture?

- Installation method of wood grain hyperbolic aluminum veneer

- Hyperbolic aluminum veneer: the new darling of architectural aesthetics

- How does aluminum veneer provide the anti-corrosion performance required for modern buildings?

- Aluminum veneer curtain wall: the "fashionable coat" of modern architecture

Frequently asked questions

- What occasions is aluminum veneer suitable for?

- What are the special points to pay attention to when installing aluminum veneer?

- How to check the quality of aluminum veneer?

- How to choose and purchase aluminum veneer?

- What environmental issues should be paid attention to in the production and use of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What are the special points to pay attention to when installing aluminum veneer?

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: 2022-03-02 19:25:02

- Click:0

1、 Preparation work

1. Develop a detailed construction plan: Before installing aluminum veneer, a comprehensive and detailed construction plan needs to be developed to ensure the safe and smooth progress of the construction process. Specifically, preparation work such as construction drawings and scaffolding should be done according to the actual situation.

2. Selecting appropriate tools and materials: When installing aluminum veneer, it is necessary to use appropriate tools and materials, such as high-strength steel wire ropes, cranes, baskets, pulleys, screws, etc. At the same time, when selecting materials, priority should be given to products with good quality and stable performance to ensure safety and quality.

3. Check the quality of the base layer: Before installing the aluminum veneer, it is necessary to inspect the base layer to ensure that it is intact and free of quality problems such as cracks. If any problems are found, the base layer needs to be repaired first before installing the aluminum veneer.

2、 Precautions during installation

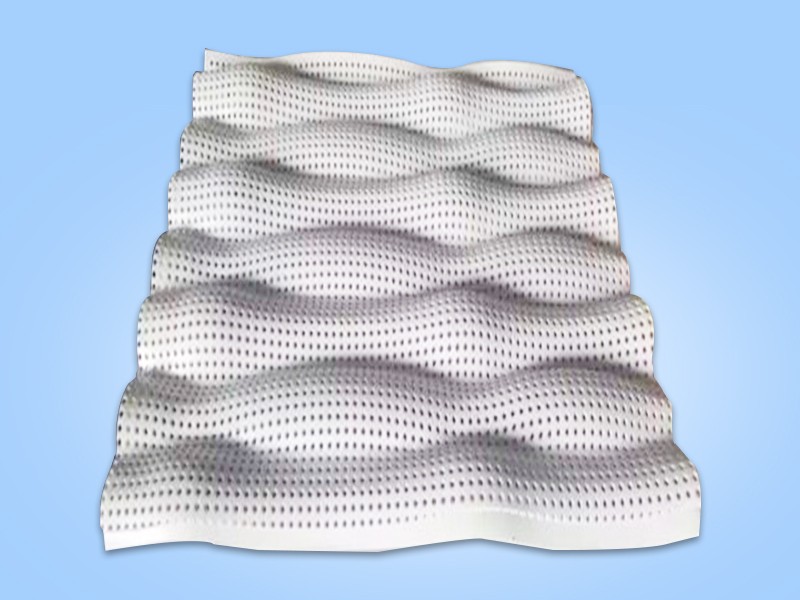

1. Grasp the installation position and direction: When installing aluminum veneer, it is necessary to strictly follow the design requirements for installation position and direction to avoid installation deviation or misalignment. At the same time, it is necessary to ensure that the connections between various parts are tight, and there should be no looseness at the connections.

2. Reasonably adjust the spacing between aluminum veneers: When installing aluminum veneers, it is necessary to adjust the spacing between them reasonably to ensure that the overall effect of the aluminum veneers is beautiful and elegant. Meanwhile, during the installation process, it is also necessary to ensure that the gap between the aluminum veneer and the substrate is not greater than 4mm.

3. Pay attention to construction temperature and humidity: When installing aluminum veneer, it is necessary to pay attention to environmental factors such as temperature and humidity. Generally speaking, the suitable construction temperature is 5 ℃~35 ℃. Construction should not be carried out in high temperature, low temperature or high humidity environments, otherwise it will affect the construction effect and quality.

3、 Maintenance and upkeep

1. Regular inspection and timely maintenance: Aluminum veneer may encounter some problems during long-term use, such as detachment, deformation, damage, etc. Therefore, after installation, the aluminum veneer should be regularly inspected and maintained, and any issues should be promptly addressed to ensure its aesthetics and safety.

2. Avoid using chemicals: During the maintenance process of aluminum veneer, it is advisable to avoid using chemical cleaning agents and solvents containing acidic and alkaline components as much as possible to avoid damaging the coating on the surface of the aluminum veneer. Generally speaking, water or mild soapy water can be used for cleaning and maintenance.

3. Preventing mechanical impact and scratches: During the use of aluminum veneer, attention should be paid to avoiding mechanical impact and scratches to avoid damage to the surface of the aluminum veneer and affecting its appearance.

4、 Relationship with environmental protection

1. Choose environmentally friendly materials: When installing aluminum veneer, priority should be given to selecting environmentally friendly materials to reduce pollution to the environment and impact on health. At the same time, attention should be paid to the handling and recycling of materials, and good garbage classification and environmental protection work should be done.

2. Avoiding environmental pollution: When carrying out aluminum veneer construction, it is necessary to pay attention to preventing dust and noise from affecting the environment, minimizing the emission of pollutants as much as possible, and doing a good job in environmental protection.

3. Pay attention to construction safety: During the installation of aluminum veneer, attention should be paid to construction safety, comply with environmental regulations and operating procedures, and ensure the personal and environmental safety of construction personnel.

5、 Summary

Through the detailed explanation of the above four aspects, we can see that there are many areas that need special attention in the installation of aluminum veneer, such as preparation work, precautions during installation, maintenance, and the relationship with environmental protection. Only by doing a good job in these aspects can we ensure that aluminum veneer has high quality, high efficiency, and high environmental requirements during use.

Customer service QQ

Customer service QQ