Industry information

Company News

- Unveiling the unique charm and wide application of fluorocarbon aluminum veneer

- The industrial chain structure and optimization of aluminum veneer industry

- Hyperbolic aluminum veneer: a building material that combines fashion and technology

- Fluorocarbon aluminum veneer: the new darling of modern architecture

- The beautiful transformation of hyperbolic aluminum veneer witnesses a new height in architectural art

Industry dynamics

- Selection of customized aluminum veneer to optimize building performance

- Safe and environmentally friendly fluorocarbon curved aluminum veneer provides protection for buildings

- Aluminum veneer curtain wall: the "gorgeous coat" of modern architecture

- Fluorocarbon aluminum veneer: the 'invisible guardian' of the construction industry

- Exploring the Charm and Application of Hyperbolic Aluminum Veneer

Frequently asked questions

- What environmental issues should be paid attention to in the production and use of aluminum veneer?

- What is the production process of aluminum veneer?

- What is the development prospect of aluminum veneer?

- How to choose and purchase aluminum veneer?

- What occasions is aluminum veneer suitable for?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Quality testing standards for fluorocarbon aluminum veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: 2022-02-27 04:34:56

- Click:0

Fluorocarbon aluminum veneer, as a new type of building material, its quality inspection is an important means to ensure building safety and effectiveness. To ensure the quality of fluorocarbon aluminum veneer, it is necessary to establish a complete set of quality inspection standards. The following will provide a detailed introduction to the quality inspection standards for fluorocarbon aluminum veneer.

1、 Material performance testing

The main materials of fluorocarbon aluminum veneer are aluminum alloy and fluorocarbon coating, so performance testing of the materials is required. This mainly includes testing of performance indicators such as material strength, stiffness, and corrosion resistance. It is also necessary to conduct color and gloss tests on fluorocarbon coatings to ensure the decorative effect and durability of fluorocarbon aluminum veneers.

2、 Structural design testing

The structural design of fluorocarbon aluminum veneer is also one of the important factors affecting its quality. Structural design testing mainly includes aspects such as framework structure and connection methods. It is necessary to test the structural stability, load-bearing capacity and other indicators of fluorocarbon aluminum veneer to ensure the overall stability and safety of fluorocarbon aluminum veneer.

3、 Appearance quality inspection

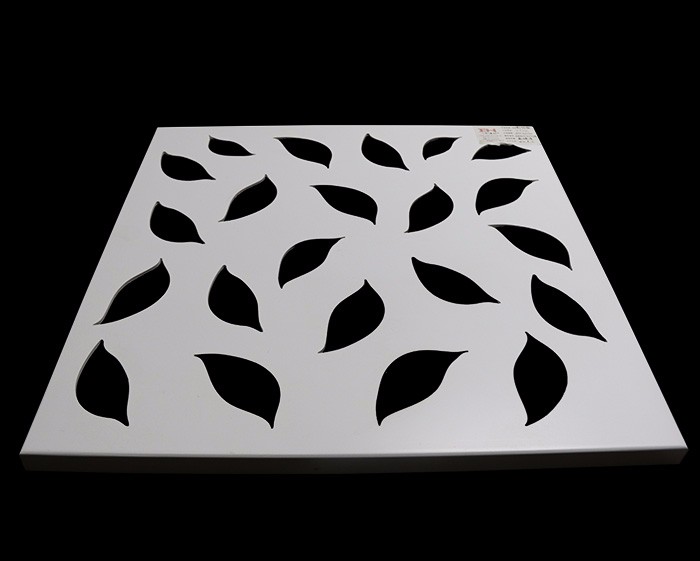

The appearance quality of fluorocarbon aluminum veneer is also one of its important indicators of quality. It is necessary to test the color, surface glossiness, flatness, and other aspects of fluorocarbon aluminum veneer to ensure its decorative effect and aesthetic appeal.

4、 Waterproof performance testing

Fluorocarbon aluminum veneer has good waterproof performance, so its waterproof performance needs to be tested. This mainly includes water pressure testing and leakage detection to verify whether the waterproof effect of fluorocarbon aluminum veneer meets the requirements.

5、 Fire performance testing

Fluorocarbon aluminum veneer has good fire resistance, so its fire resistance needs to be tested. This mainly includes combustion experiments and fire resistance limit tests to verify whether the fire resistance performance of fluorocarbon aluminum veneer meets the requirements.

6、 Summary

The above is a detailed introduction to the quality inspection standards for fluorocarbon aluminum veneer. In practical applications, it is necessary to customize according to the actual situation to achieve the best results. Attention should also be paid to the accuracy of the testing equipment and the scientificity of the testing methods to ensure the accuracy and reliability of the testing results.

Customer service QQ

Customer service QQ