Industry information

Company News

- Aluminum veneer customization, creating personalized space and new fashion

- Irregular aluminum veneer: the personalized business card of architecture

- Fluorocarbon aluminum veneer: the new darling of architectural aesthetics

- Explore the extraordinary charm of irregular aluminum veneer

- Aluminum veneer curtain wall: the beauty of architecture lies within a single panel

Industry dynamics

- Installation method of aluminum ceiling

- Fluorocarbon aluminum veneer: an innovative element in architectural aesthetics

- Irregular aluminum veneer: the new darling of architectural aesthetics

- Aluminum veneer has strong antioxidant capacity

- Market prospects and development trends of special-shaped 1.5mm aluminum veneer

Frequently asked questions

- What is the production process of aluminum veneer?

- What occasions is aluminum veneer suitable for?

- How to check the quality of aluminum veneer?

- What is the development prospect of aluminum veneer?

- How to choose and purchase aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What are the types of products from aluminum veneer manufacturers?

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: 2022-03-04 23:38:12

- Click:0

Aluminum veneer, as a building decoration material, has various types of products. Below, we will provide a detailed introduction to the product categories of aluminum veneer manufacturers.

1、 Regular series

1. Standard board: Standard board is one of the most common products of aluminum veneer manufacturers, and its size and thickness can be customized according to customer needs.

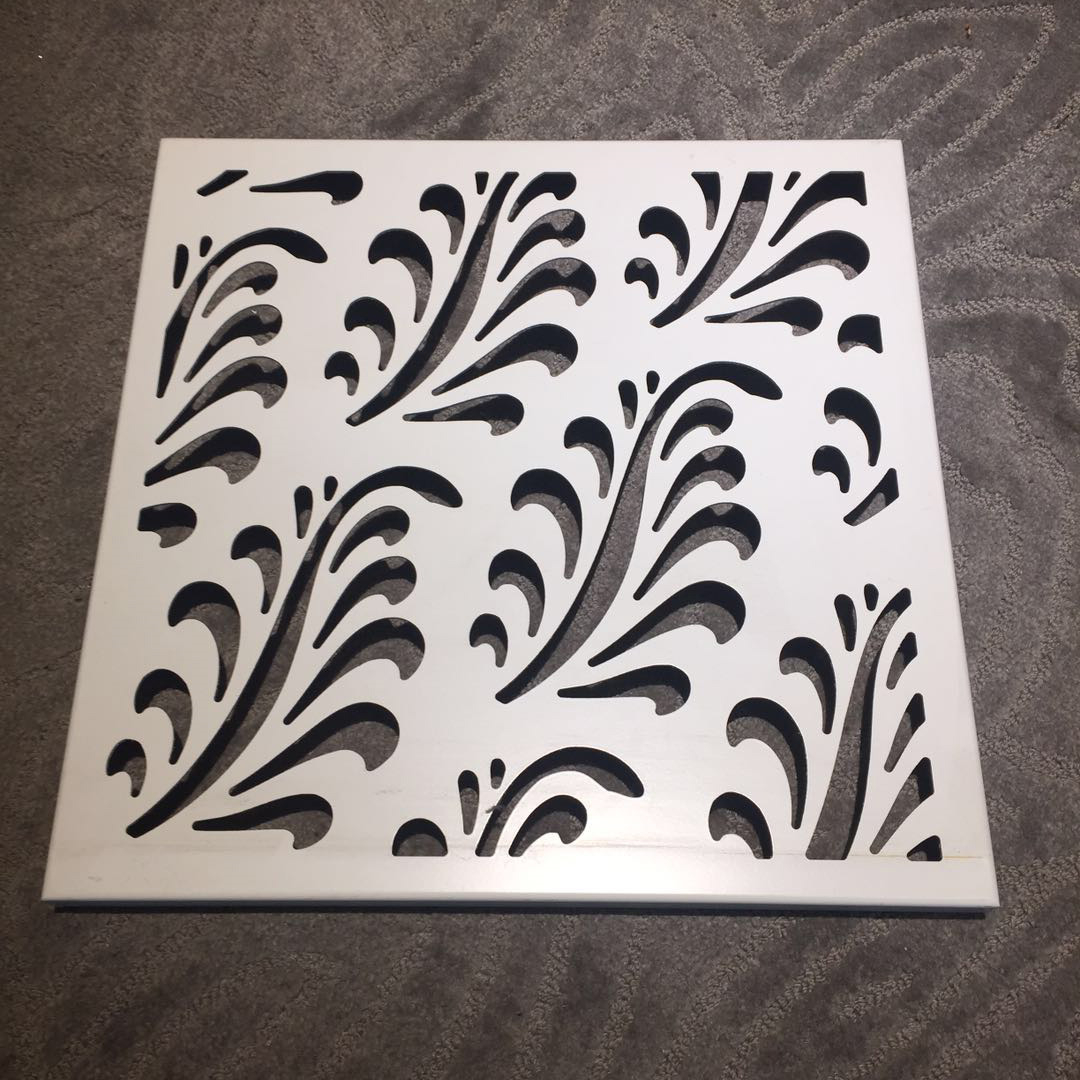

2. Irregular shaped plate: Irregular shaped plate refers to aluminum veneer with irregular shapes, which can be customized according to customer requirements.

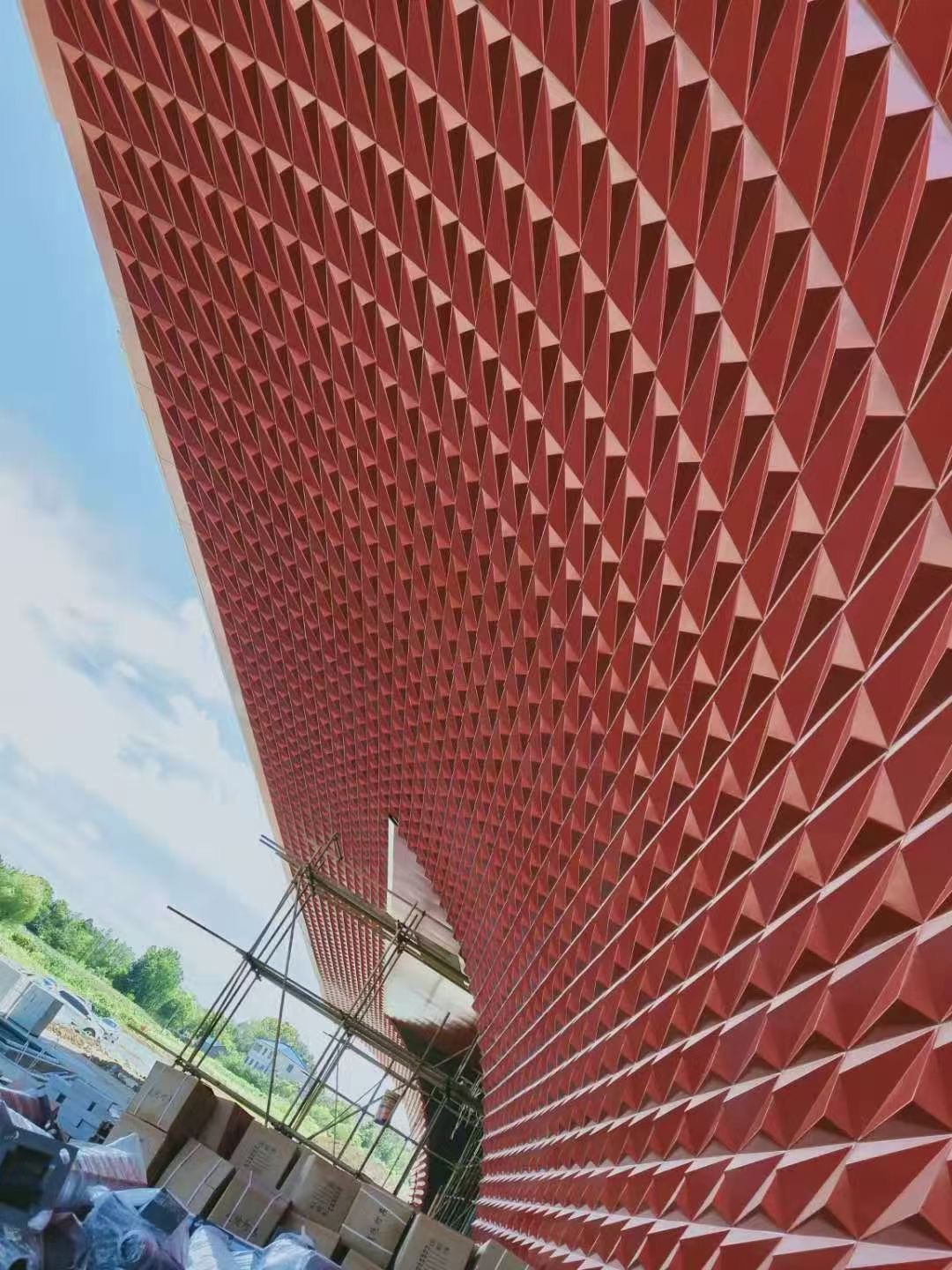

3. Hyperbolic panel: Hyperbolic panel refers to aluminum veneer with a curved surface, which can enhance the aesthetic appeal of buildings.

2、 Surface treatment series

1. Spray coating series: The spray coating series is a process of coating the surface of aluminum veneer to achieve anti-corrosion and rust prevention effects.

2. Anodizing series: Anodizing series is the process of anodizing the surface of aluminum veneer to improve its hardness and wear resistance.

3. Powder coating series: The powder coating series is a powder coating treatment applied to the surface of aluminum veneer to improve its weather resistance and decorative properties.

3、 Processing Technology Series

1. brushed panel: brushed panel refers to the process of brushed processing on the surface of aluminum veneer to increase its texture and decorative value.

2. Mirror panel: Mirror panel refers to the polishing treatment of the surface of aluminum veneer to increase its glossiness and decorative value.

3. Carving panel: Carving panel refers to the process of carving and processing the surface of aluminum veneer to increase its artistic and decorative value.

4、 Application Field Series

1. Building curtain wall series: Building curtain wall is one of the most common application areas for aluminum veneer manufacturers, which can be used for decoration and protection of building exterior walls, roofs, and other parts.

2. Interior Decoration Series: Interior decoration is another important application area for aluminum veneer manufacturers, which can be used for decoration of indoor ceilings, partitions, doorplates, and other parts.

3. Transportation series: Transportation is one of the emerging application areas for aluminum veneer manufacturers, which can be used for the manufacturing and maintenance of vehicles such as cars and airplanes.

The product categories of aluminum veneer manufacturers mainly include conventional series, surface treatment series, processing technology series, and application field series. In the actual operation process, it is necessary to follow relevant norms and standards for operation and management, strengthen communication and collaboration, and improve work efficiency and quality level. We also need to pay attention to issues such as environmental protection and energy conservation, continuously innovate and improve products and services, and meet the needs of customers and the expectations of society.

Customer service QQ

Customer service QQ