Industry information

Company News

- Exploring Fluorocarbon Aluminum Veneer: The New Favorite of Modern Architecture

- Irregular aluminum veneer: the personalized business card of architecture

- Exploring the unique charm of irregular aluminum veneer

- Aluminum veneer: creating a new trend in modern architecture

- Market expansion and sales strategy of aluminum veneer

Industry dynamics

- Hyperbolic aluminum veneer: a new trend in aluminum materials and a new landscape in architecture

- What issues should be noted in the installation and maintenance of aluminum veneer?

- Carving 2.0mm aluminum veneer opens a new chapter in architectural design

- Color matching techniques for aluminum veneer

- Aluminum veneer customization, creating personalized spatial aesthetics

Frequently asked questions

- What is the approximate price of aluminum veneer?

- What is the development prospect of aluminum veneer?

- How to check the quality of aluminum veneer?

- What environmental issues should be paid attention to in the production and use of aluminum veneer?

- What is the production process of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

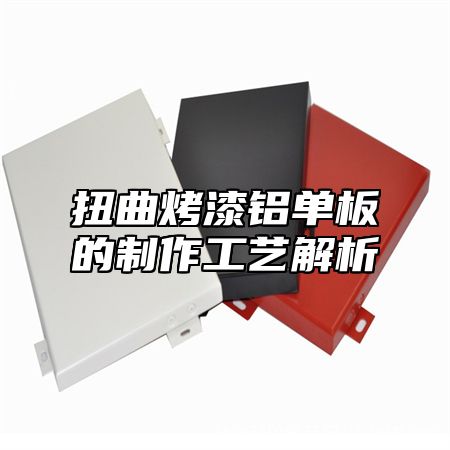

Analysis of the production process of twisted painted aluminum veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: 2022-03-03 07:56:33

- Click:0

Twisted painted aluminum veneer is a high-end building decoration material, and its production process is very complex. This article will provide a detailed analysis from the aspects of raw material procurement, processing and manufacturing, surface treatment, etc., to help everyone better understand the production process of twisted painted aluminum veneer.

1、 Raw material procurement

The main raw materials for twisted painted aluminum veneer are aluminum plates and coatings. Aluminum plate is the basic material for making twisted painted aluminum veneer, generally using high-quality aluminum alloy plates such as 1100, 3003, 5052 series. And coating is one of the key factors determining the quality of twisted baked aluminum veneer, usually using polyester baked paint or fluorocarbon baked paint.

2、 Processing and Manufacturing

1. Cutting: First, it is necessary to accurately cut the aluminum plate to ensure that the dimensional accuracy and edge smoothness of the aluminum plate meet the requirements.

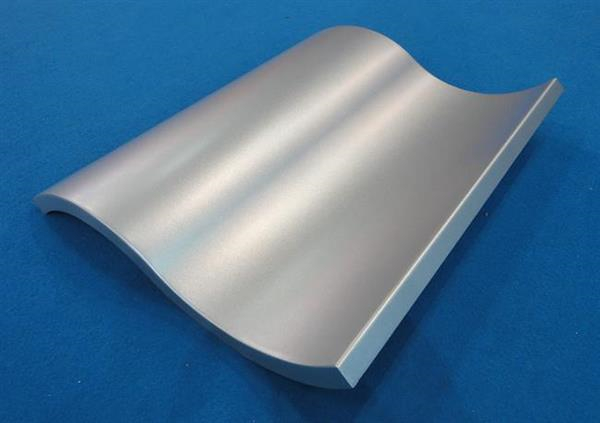

2. Bending: While ensuring the strength of the aluminum plate, bend it according to the design requirements to form the desired bending shape.

3. Punching: According to the design requirements, punch the required holes and patterns on the aluminum plate.

4. Welding: Connect multiple aluminum plates together by welding to form a complete twisted painted aluminum veneer.

3、 Surface treatment

1. Remove oil stains: Clean the oil and dirt on the surface of the aluminum plate to facilitate the adhesion of subsequent coatings.

2. Polishing: Use sandpaper and other tools to polish the surface of the aluminum plate to make it smoother and smoother.

3. Spray primer: Spray a layer of primer on the surface of the aluminum plate to enhance the adhesion between the coating and the aluminum plate.

4. Spray topcoat: After the primer is dry, spray another layer of topcoat to give the desired color and gloss to the twisted painted aluminum veneer surface.

4、 Quality inspection

After completing the above steps, it is necessary to conduct strict quality inspection on the twisted painted aluminum veneer, including dimensional accuracy, surface smoothness, coating thickness, and other aspects. Only products that have passed strict inspection and are qualified can be put on the market for sale.

5、 Summary

The production process of twisted painted aluminum veneer is very complex and requires multiple steps to complete. Through a detailed introduction to raw material procurement, processing and manufacturing, surface treatment, etc., we believe that everyone has gained a deeper understanding of the production process of twisted painted aluminum veneer. In the future, with the continuous advancement and improvement of technology, the application prospects of twisted painted aluminum veneer will also be broader.

Customer service QQ

Customer service QQ