Frequently asked questions

Company News

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Irregular aluminum veneer: the fashionable new favorite of modern architecture

- Hyperbolic aluminum veneer: the integration of art and technology in modern architecture

- Fluorocarbon aluminum veneer: the fashionable choice for modern architecture?

- Fluorocarbon aluminum veneer: the "invisible warrior" of modern architecture

Industry dynamics

- Aluminum veneer curtain wall, the light luxury choice of architectural art

- Fluorocarbon aluminum veneer: the "fashion trendsetter" in the construction industry

- Aluminum veneer customization, creating an artistic journey of personalized space

- Unveiling the Charm of Fluorocarbon Aluminum Veneer: The New Favorite of Environmental Protection Decoration

- Light luxury choice 1.5mm aluminum veneer exterior wall decoration

Frequently asked questions

- What are the special points to pay attention to when installing aluminum veneer?

- What environmental issues should be paid attention to in the production and use of aluminum veneer?

- What is the development prospect of aluminum veneer?

- How to check the quality of aluminum veneer?

- How to choose and purchase aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What are the surface treatment methods for aluminum veneer?

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: February 28, 2025 19:49:27

- Click:0

What are the surface treatment methods for aluminum veneer?

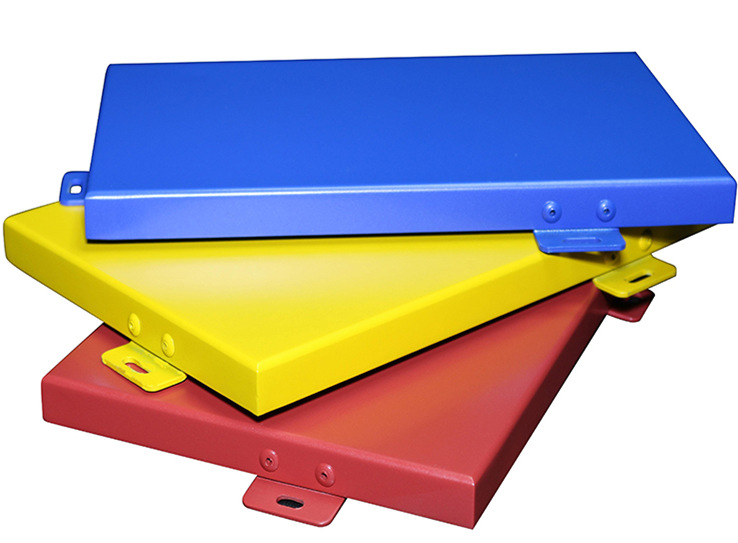

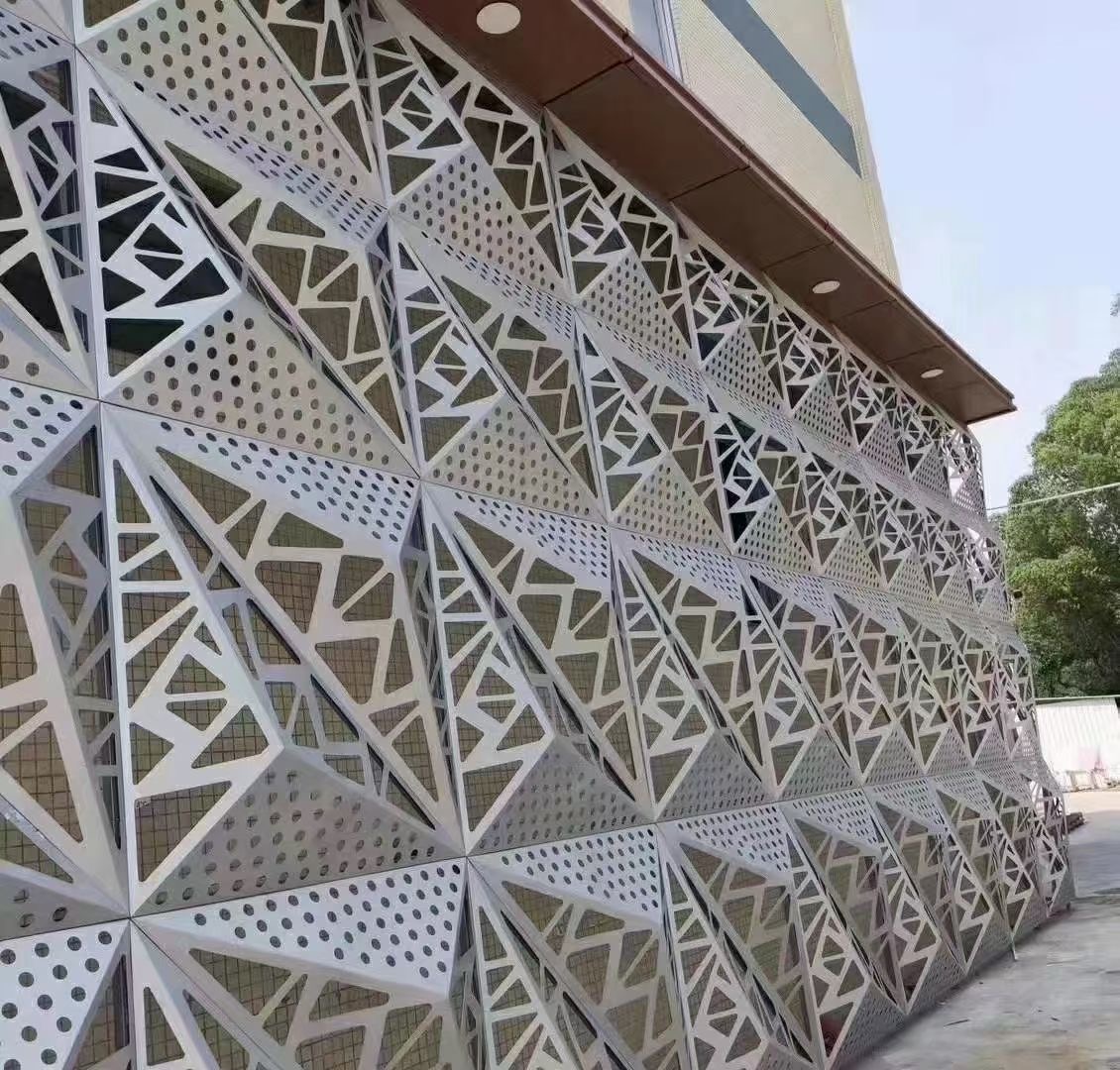

Aluminum veneer, as a common building decoration material, is widely used in fields such as building facades and interior decoration. In order to enhance its aesthetics and durability, surface treatment of aluminum veneer is essential. Below, we will provide a detailed introduction to the surface treatment methods of aluminum veneer from four aspects: anti-corrosion treatment, coating treatment, embossing treatment, and oxidation treatment.

1、 Anti corrosion treatment

1. Anodizing: Anodizing is a commonly used surface treatment method that increases the corrosion resistance of aluminum veneer by forming an oxide film on its surface. This film layer has high hardness and wear resistance, which can effectively prevent aluminum veneer from being corroded by external environment.

2. Chemical coating: Chemical coating is the use of chemical reactions to form a protective film on the surface of aluminum veneer, improving its corrosion resistance. Common chemical coating methods include oxidation method, sulfuric acid method, etc., and suitable methods can be selected according to actual needs.

3. Spraying anti-corrosion paint: Spraying anti-corrosion paint is a simple and economical method of anti-corrosion treatment, which increases the corrosion resistance of aluminum veneer by spraying a layer of anti-corrosion paint on its surface. This method is suitable for places where appearance requirements are not high.

2、 Coating treatment

1. Fluorocarbon coating: Fluorocarbon coating is a common coating treatment method, which applies a coating containing fluorocarbon resin on the surface of aluminum veneer to form a dense coating. This coating has excellent weather resistance and stain resistance, which can maintain the long-term beauty of aluminum veneer.

2. Powder coating: Powder coating is an environmentally friendly and durable coating treatment method. After spraying powder coating on the surface of aluminum veneer, it is cured and attached to the surface by baking. This coating has high weather resistance and wear resistance, making it suitable for outdoor environments.

3. Polyester coating: Polyester coating is an economical and practical coating treatment method, which forms a protective layer on the surface of aluminum veneer by coating polyester resin coating. This coating has good weather resistance and mechanical properties, and is widely used in the field of interior decoration.

3、 Embossing treatment

1. Mechanical embossing: Mechanical embossing is a common surface treatment method for aluminum veneer, which applies pressure on the surface of the aluminum veneer to create a certain texture pattern. This processing method can enhance the aesthetics and tactile feel of aluminum veneer, with common textures including lines, dots, and geometric patterns.

2. Chemical embossing: Chemical embossing is a treatment method that uses chemical corrosion to form texture patterns on the surface of aluminum veneer. By immersing aluminum veneer in a specific corrosive solution, different texture shapes can be created to enhance its decorative effect.

3. Embossing treatment: Embossing treatment is the process of applying a certain amount of pressure on the surface of aluminum veneer to create a pattern with a textured texture. This processing method is commonly used in indoor decoration, which can increase the three-dimensional and tactile sense of the space.

4、 Oxidation treatment

1. Anodizing treatment: Anodizing treatment is the process of subjecting the surface of an aluminum veneer to a certain voltage and conducting an oxidation reaction in an electrolyte to form a dense oxide film. This processing method can improve the hardness and wear resistance of aluminum veneer, and increase its aesthetics.

2. Chemical oxidation: Chemical oxidation is a simple oxidation treatment method that forms an oxide film on the surface of aluminum veneer by using a chemical liquid for oxidation treatment. This film layer has certain corrosion resistance and can also make aluminum veneers appear in different colors.

3. Anodizing: Anodizing is the process of depositing dyes into an oxide film on the surface of aluminum veneer through electrolysis or immersion, resulting in different colors. This processing method can increase the decorative and aesthetic appeal of aluminum veneer.

5、 Summary:

Through anti-corrosion treatment, coating treatment, embossing treatment, and oxidation treatment, the surface performance of aluminum veneer can be effectively improved, increasing its aesthetics and durability. In practical applications, suitable surface treatment methods can be selected according to needs to meet different environmental and decorative requirements.

Customer service QQ

Customer service QQ