Corporate News

Company News

- Fluorocarbon aluminum veneer: a perfect combination of architectural aesthetics and technology

- Aluminum veneer customization, creating a new trend of personalized space!

- Unveiling Curtain Wall Aluminum Veneer: The 'Invisible Hero' of Modern Architecture

- Hyperbolic aluminum veneer: a building material that combines fashion and technology

- Aluminum veneer curtain wall: the beauty of modern architecture, revealing the story behind it

Industry dynamics

- Price factors of aluminum veneer

- Aluminum veneer: lightweight decoration, green future

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer curtain wall, the finishing touch of architectural aesthetics

- 2. "Hyperbolic aluminum veneer: a perfect fusion of innovation and aesthetics" 3 Exploring Hyperbolic Aluminum

Frequently asked questions

- How to check the quality of aluminum veneer?

- What are the special points to pay attention to when installing aluminum veneer?

- How to choose and purchase aluminum veneer?

- What are the surface treatment methods for aluminum veneer?

- What are the advantages of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Production process and flow of aluminum veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: February 27, 2025 15:02:55

- Click:0

Production process and flow of aluminum veneer

Abstract: This article will provide a detailed introduction to the production process and workflow of aluminum veneer. It mainly includes the following four aspects: raw material preparation, processing and forming of aluminum veneer, coating treatment and surface decoration, final product inspection and packaging.

1、 Raw material preparation

1. Material selection: In the production process of aluminum veneer, the first step is to choose suitable aluminum alloy materials. Commonly used aluminum alloys include AA1100, AA3003, AA5005, etc. Different alloys have different strengths, corrosion resistance, and processability. Choose the appropriate aluminum alloy according to your needs.

2. Raw material cutting: The selected aluminum alloy sheet needs to be cut according to the size requirements of the product, usually using a CNC cutting machine for precise cutting to ensure that the size of each aluminum veneer is consistent.

3. Surface treatment: The cut aluminum veneer needs to be surface treated using common methods such as anodizing and spraying. Anodizing can increase the corrosion resistance and hardness of aluminum veneer, while spraying can provide a wide range of color choices and corrosion protection.

2、 Processing and forming of aluminum veneer

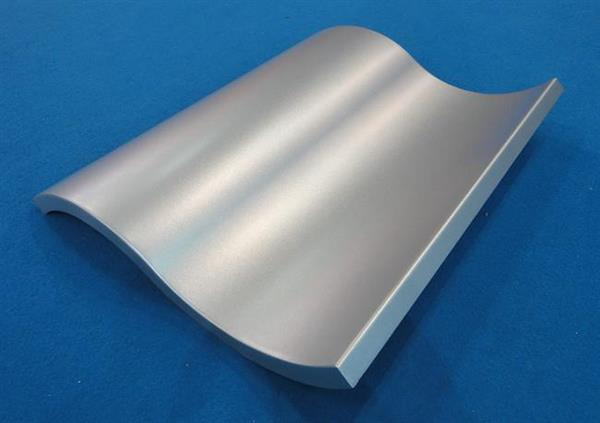

1. Bending and Forming: Aluminum veneers that have undergone surface treatment are bent and formed to meet different design requirements. Common processing methods include flat bending, U-shaped bending, and V-shaped bending. By processing and forming, various shapes of aluminum veneers can be produced, such as flat plates, corrugated plates, and dome plates.

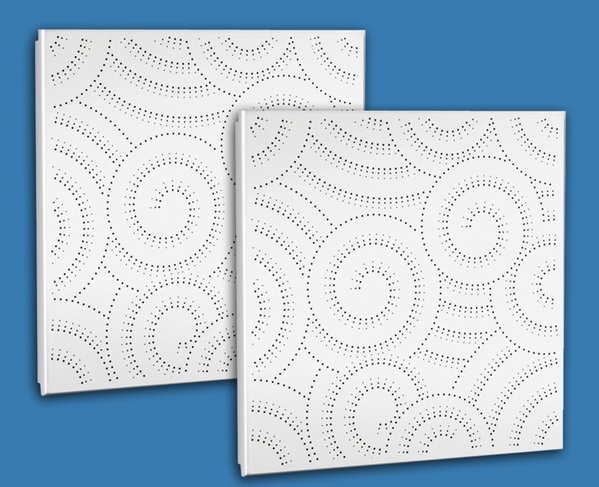

2. Holes and cutting: Processing holes and cutting on aluminum veneer according to design requirements. Holes can be used for fixed installation and ventilation, while cutting can achieve complex patterns.

3. Welding and connection: Welding and connecting multiple aluminum veneers together to form a larger overall structure. Usually, rivets, welding, or bonding are used for connection to ensure the stability and firmness of the aluminum veneer.

3、 Coating treatment and surface decoration

1. Primer coating: Apply primer on the surface of aluminum veneer to improve the adhesion and durability of the coating. Primer can also fill in surface irregularities and minor defects, making subsequent coatings more uniform.

2. Topcoat spraying: Spray the topcoat after the primer has dried. Topcoat not only provides a wide range of color options, but also enhances the appearance and texture of aluminum veneer. Common topcoats include fluorocarbon paint, polyester paint, and polyurethane paint.

3. Surface decoration: According to design requirements, various surface decorations can be applied to aluminum veneer, such as wood grain, stone grain, and metal texture. These decorations can be achieved through methods such as printing, transfer printing, or heat transfer printing, adding beauty and uniqueness to the product.

4、 Final product inspection and packaging

1. Quality inspection: In the final stage of aluminum veneer production, it is necessary to conduct quality inspection on the finished product. Mainly inspect the dimensional accuracy, surface quality, and coating adhesion of aluminum veneer to ensure that the product meets the standard requirements.

2. Surface treatment testing: Testing the quality of coatings, including weather resistance, corrosion resistance, and color stability. Common detection methods include scratch testing, salt spray testing, and color difference testing.

3. Packaging and transportation: Aluminum veneer products are packaged and protected using appropriate packaging methods to prevent damage during transportation. Usually packaged in wooden or cardboard boxes, with appropriate cushioning materials added to provide additional protection.

5、 Summary:

From the above explanation, it can be seen that the production process and flow of aluminum veneer are complex and refined processes. From raw material preparation to final product quality inspection and packaging, every step needs to be strictly controlled and executed. The reasonable application of these processes and procedures can not only ensure the quality and performance of aluminum veneer products, but also meet the needs and design requirements of different customers.

Customer service QQ

Customer service QQ