Industry information

Company News

- Aluminum veneer curtain wall, a new interpretation of the beauty of architecture

- Aluminum veneer curtain wall: the beauty of architecture, witness to details

- Fluorocarbon aluminum veneer: the fashionable new darling of the construction industry?

- Fluorocarbon aluminum veneer: the new darling of architectural aesthetics

- Aluminum veneer: the "fashionable coat" of modern architecture

Industry dynamics

- Fluorocarbon aluminum veneer: a fashionable choice for modern architecture

- The beauty of the transformation of aluminum veneer curtain walls separated by a board

- Hyperbolic aluminum veneer: the new darling of architectural aesthetics

- Hyperbolic aluminum veneer: the artistic new darling of the aluminum industry

- Application examples of aluminum veneer in landscape design

Frequently asked questions

- What environmental issues should be paid attention to in the production and use of aluminum veneer?

- What is the approximate price of aluminum veneer?

- What occasions is aluminum veneer suitable for?

- What are the special points to pay attention to when installing aluminum veneer?

- How to check the quality of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Application scope and applicable industries of 3mm aluminum veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: 2022-03-16 05:30:48

- Click:0

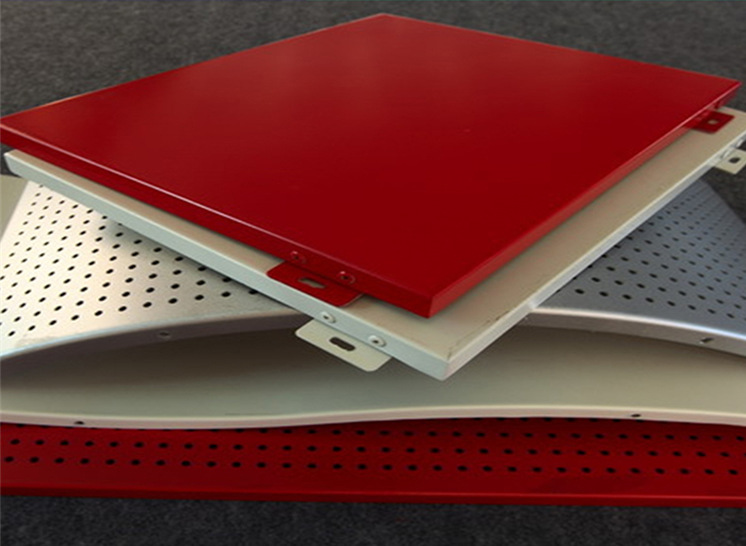

As a new type of building material, 3mm aluminum veneer has a wide range of applications and suitable industries. This article will introduce the scope of use and applicable industries of 3mm aluminum veneer from multiple aspects.

1、 Building curtain wall field

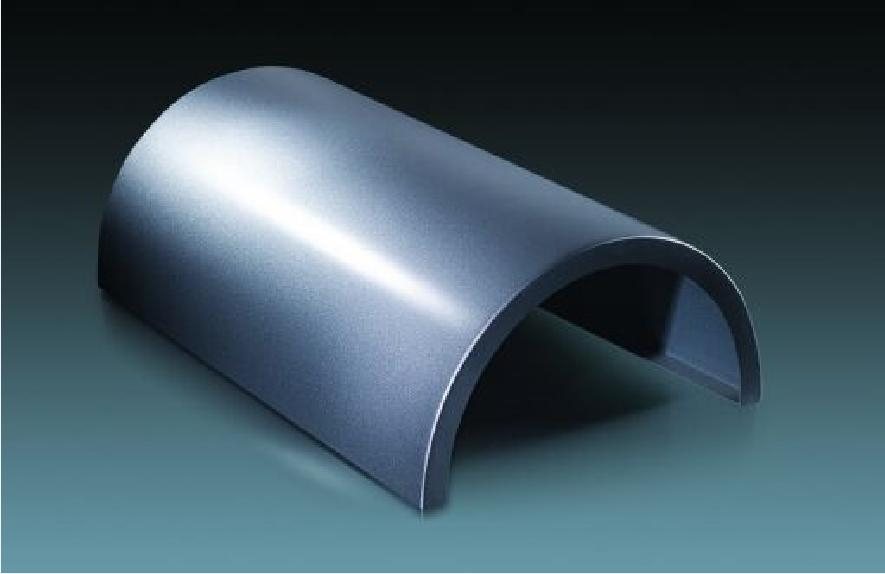

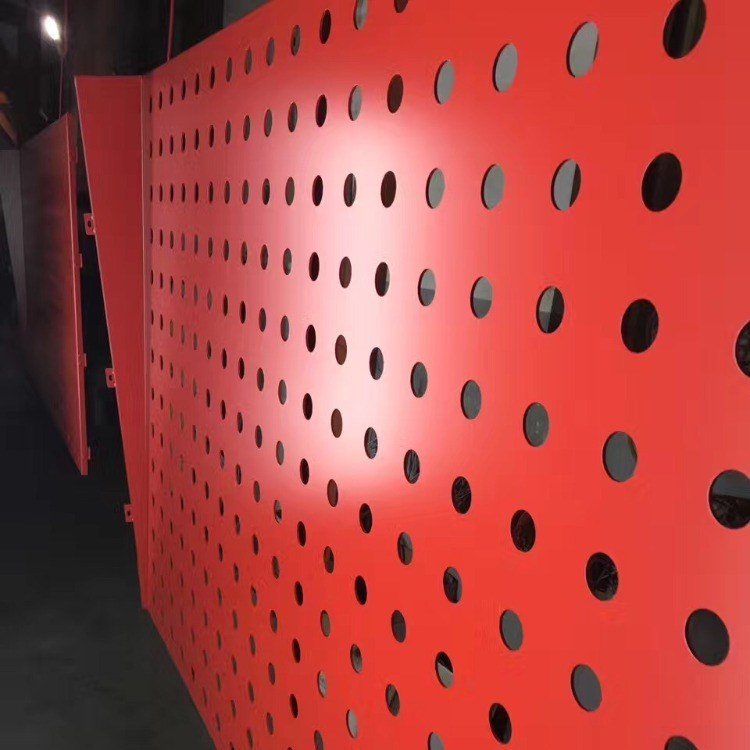

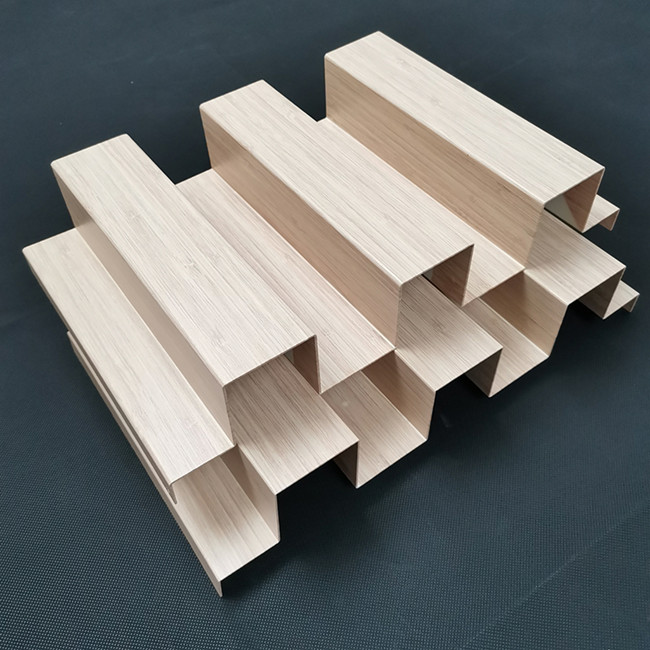

3mm aluminum veneer is one of the commonly used decorative materials in the field of building curtain walls. Its lightweight, high strength, corrosion resistance and other characteristics have made it widely used in the field of building curtain walls. The surface treatment technology of 3mm aluminum veneer can also achieve various color and texture effects, enhancing its decorative effect.

2、 Interior decoration field

3mm aluminum veneer can be used not only in the field of building curtain walls, but also in the field of interior decoration. Its surface treatment technology can achieve various color and texture effects, meeting the decoration needs of different occasions. 3mm aluminum veneer also has good thermal insulation and fire resistance, which conforms to the environmental protection concept of modern society.

3、 Transportation infrastructure field

3mm aluminum veneer also has a wide range of applications in the field of transportation facilities. For example, in public places such as subway stations and airports, 3mm aluminum veneer can be used as a decorative material, enhancing the aesthetics and practicality of the place. 3mm aluminum veneer also has good corrosion resistance and fire resistance, ensuring the safety and stability of public places.

4、 Other industry sectors

In addition to the above-mentioned industries, 3mm aluminum veneer can also be applied to other industries. For example, in fields such as billboards, exhibition halls, sports venues, etc., 3mm aluminum veneer can be used as a decorative material to enhance the aesthetics and practicality of the venue. In fields such as solar panels, 3mm aluminum veneer also has certain application prospects.

5、 Case sharing

The following is a successful application case of 3mm aluminum veneer: A commercial complex used 3mm aluminum veneer as exterior wall decoration material, and achieved good decorative effect and anti-corrosion performance through reasonable design and construction plan. The commercial complex also adopts scientific maintenance methods to ensure its long-term effectiveness and safety. This application solution not only improves the overall aesthetics and practicality of the building, but also conforms to the environmental protection concept of modern society.

3mm aluminum veneer has a wide range of applications and suitable industries. Only by selecting appropriate materials and surface treatment methods based on specific usage environments and requirements can their advantages be fully utilized to meet the needs of different fields.

Customer service QQ

Customer service QQ