Industry information

Company News

- Fluorocarbon aluminum veneer: the fashionable darling of the aluminum industry, combining environmental protection and aesthetics

- Exploring the unique charm of irregular aluminum veneer: it's not just about the sheet metal!

- Irregular aluminum veneer: the new darling of architectural aesthetics

- Aluminum veneer: the fashionable "silver garment" in modern architecture

- Aluminum veneer: the fashionable "coat" of modern architecture

Industry dynamics

- Production process and advantages analysis of irregular stone patterned aluminum veneer

- The Great Wall ceiling aluminum veneer perfectly integrates traditional and modern design art

- Quality inspection and evaluation of aluminum veneer

- Aluminum veneer new fashion, the "metal fashion expert" in home decoration

- Curtain wall aluminum veneer: the beauty of architecture, details determine quality

Frequently asked questions

- What are the advantages of aluminum veneer?

- What are the surface treatment methods for aluminum veneer?

- What is the production process of aluminum veneer?

- What occasions is aluminum veneer suitable for?

- How to check the quality of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Analysis of punching process for 3mm aluminum veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: 2022-03-16 04:49:09

- Click:0

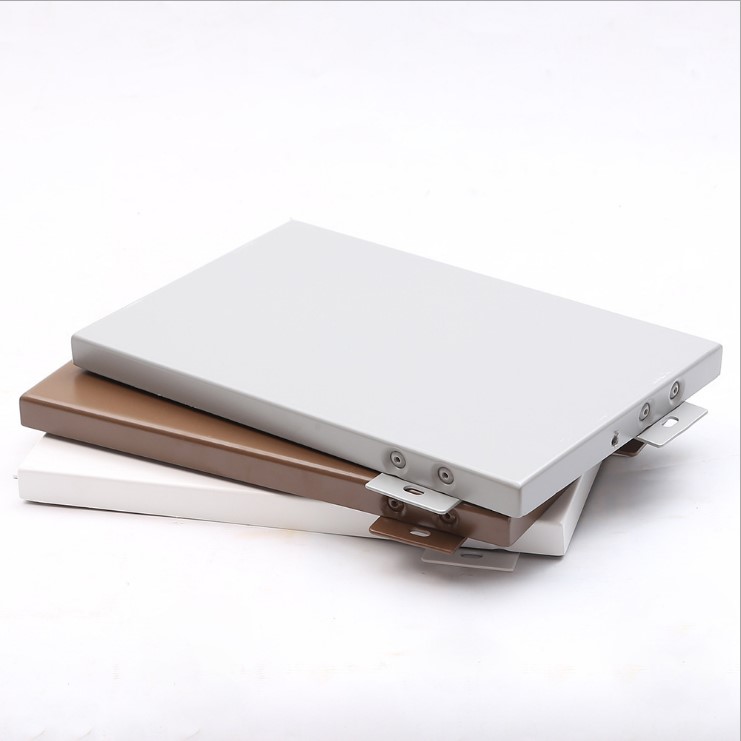

The punching process of 3mm aluminum veneer is a common method of processing aluminum veneer, which forms various sizes and shapes of holes on the surface of the aluminum veneer through punching process to achieve different decorative effects. The following will provide a detailed introduction to the principle, equipment, process flow, advantages and disadvantages of the 3mm aluminum veneer punching technology.

1、 Principle

The 3mm aluminum veneer punching process uses mechanical equipment such as punching machines or hydraulic presses to punch aluminum veneer through high-speed rotating molds, forming holes of different sizes and shapes on its surface. Punching technology can achieve various decorative effects, such as rain resistance, sound insulation, thermal insulation, ventilation, etc.

2、 Equipment

1. Punching or hydraulic press

Punching machine or hydraulic press is the main equipment for punching 3mm aluminum veneer. Its working principle is to punch the aluminum veneer through a high-speed rotating mold, forming holes of different sizes and shapes on its surface.

2. Mold

The mold is the core component of the 3mm aluminum veneer punching process, and its quality and accuracy directly affect the decorative effect of the aluminum veneer. Commonly used molds come in various shapes such as circular, square, and rectangular, and can be customized for processing according to needs.

3、 Process flow

1. Raw material preparation

As a raw material, 3mm aluminum veneer requires pre-treatment processes such as cutting, bending, and slotting to facilitate subsequent punching processing.

2. Punching processing

Place the pre processed 3mm aluminum veneer on a punch press or hydraulic press, and use a high-speed rotating mold to punch it, forming holes of different sizes and shapes on its surface. During the punching process, it is necessary to pay attention to adjusting the pressure and speed of the mold to ensure the quality and accuracy of the holes.

3. Follow up processing

After completing the punching process, it is necessary to carry out subsequent processing steps such as cleaning, deburring, and polishing on the 3mm aluminum veneer to improve its surface quality and decorative effect. At the same time, coating treatment, film sticking and other processes are also required to enhance its corrosion resistance and aesthetic appearance.

4、 Advantages and disadvantages

1. Advantages

(1) Good decorative effect: The 3mm aluminum veneer punching process can achieve various decorative effects, such as rain resistance, sound insulation, thermal insulation, ventilation, etc.

(2) Strong flexibility: The punching process of 3mm aluminum veneer can be customized according to customer needs to meet different building structures and design requirements.

(3) Low cost: Compared to other decorative materials, the 3mm aluminum veneer punching process has a higher cost advantage.

2. Disadvantages

(1) Vulnerable to damage: Due to the fragility of 3mm aluminum veneer, it is prone to damage during use.

(2) Susceptible to pollution: The holes formed by the punching process of 3mm aluminum veneer are easily contaminated, affecting its decorative effect and appearance quality.

5、 Summary

The punching process of 3mm aluminum veneer is a common method for processing aluminum veneer, which has good decorative effect and flexibility. In the future, with the continuous progress and innovation of technology, the punching process of 3mm aluminum veneer will also continue to develop and improve, bringing more new ideas and solutions to the building decoration industry.

Customer service QQ

Customer service QQ