Industry information

Company News

- Exploring Fluorocarbon Aluminum Veneer: The Gorgeous Turn of Aluminum's New Favorite

- Aluminum veneer: a fashionable element for creating modern architecture

- Aluminum veneer: the fashionable "silver garment" in modern architecture

- Recycling and environmental treatment of aluminum veneer

- Hyperbolic aluminum veneer: a building material that combines fashion and technology

Industry dynamics

- Hyperbolic aluminum veneer: innovative materials, a new chapter in architectural aesthetics

- The perfect combination of fashion and practicality: Exploring the secrets of hyperbolic aluminum veneer

- What is the difference between punched aluminum veneer and regular aluminum veneer?

- Aluminum veneer curtain wall: the secret weapon of modern architectural aesthetics

- The advantages and applications of aluminum veneer

Frequently asked questions

- What are the advantages of aluminum veneer?

- How to check the quality of aluminum veneer?

- What are the surface treatment methods for aluminum veneer?

- What are the special points to pay attention to when installing aluminum veneer?

- What occasions is aluminum veneer suitable for?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Analysis of the production process of hollow baking paint aluminum veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: March 3, 2025 03:30:36

- Click:0

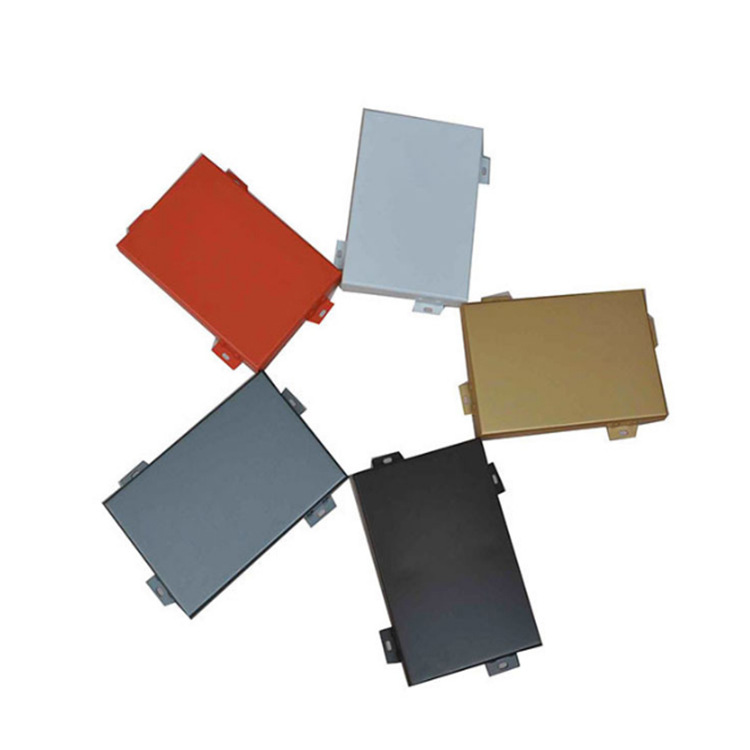

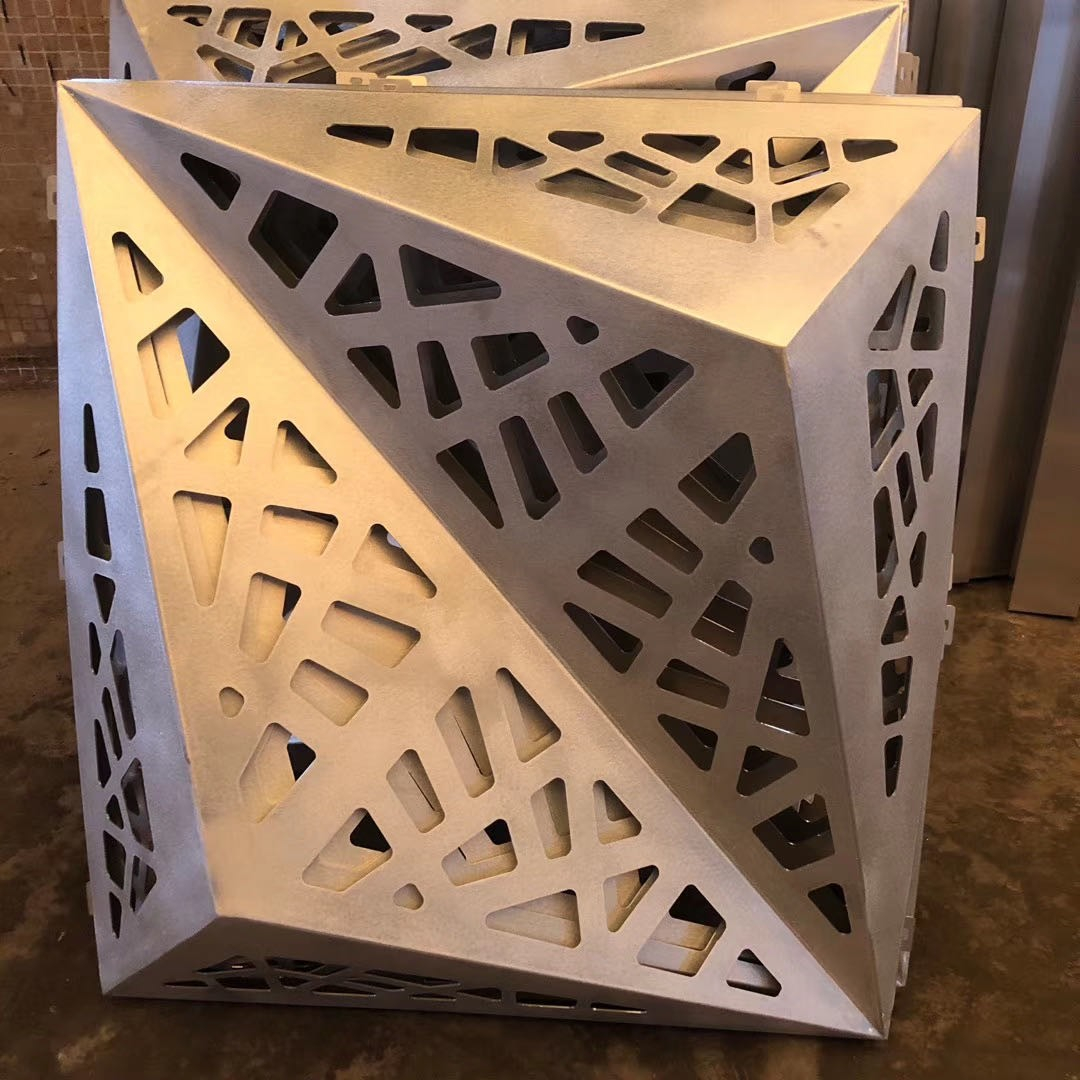

Hollow out painted aluminum veneer is a building material with a strong sense of design and decorative effect. The aluminum veneer processed through hollow out technology is more unique in surface treatment and can create a unique spatial atmosphere. The following is an analysis of the production process of hollow baking paint aluminum veneer:

1. Raw material selection: The main raw material for hollow baking paint aluminum veneer is aluminum, including different types of materials such as aluminum alloy and pure aluminum. These materials need to undergo strict screening and inspection to ensure their quality meets the requirements.

2. Cutting and processing: Cut and process the raw materials according to the design requirements to obtain the desired size and shape of the aluminum veneer. This step requires the use of professional cutting equipment and technology to ensure cutting accuracy and surface quality.

3. Stamping: Place the aluminum veneer into a stamping machine for stamping, forming the desired hollow patterns and textures. This step requires precise control of the parameters and force of the stamping machine to ensure the surface quality and strength of the aluminum veneer.

4. Surface treatment: Surface treatment of aluminum veneer after stamping, including steps such as grinding, polishing, and spraying. Spray coating is one of the most commonly used surface treatment methods, which can make the surface of aluminum veneer present different colors and textures, and improve its decorative effect.

5. Installation: Install the processed hollow painted aluminum veneer according to the design requirements, usually using the method of keel hoisting. During the installation process, attention should be paid to the position and angle of the aluminum veneer, as well as the connection method with the keel, to ensure the stability and safety of the entire building structure.

The production process of hollow baking paint aluminum veneer requires multiple processes and strict quality control to produce high-quality products. These processes not only ensure the quality and performance of aluminum veneer, but also improve its decorative effect and service life. In the future, as people's requirements for indoor environments continue to increase, it is believed that hollow baked paint aluminum veneer will play an increasingly important role in the field of architecture.

Customer service QQ

Customer service QQ