Industry information

Company News

- Hyperbolic aluminum veneer: an artistic choice in modern architecture

- Irregular aluminum veneer: the new darling of creative architecture

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Curtain Wall Aluminum Veneer: The Beauty of Architecture, One Board Sees the True Chapter!

- The beautiful transformation of hyperbolic aluminum veneer witnesses a new height in architectural art

Industry dynamics

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Application of new material fluorocarbon aluminum veneer

- What is the weather resistance of fluorocarbon aluminum veneer?

- Application fields of stone patterned hyperbolic aluminum veneer

- Aluminum veneer: a fresh breeze in the construction industry, providing you with a unique visual feast

Frequently asked questions

- How to check the quality of aluminum veneer?

- What is the approximate price of aluminum veneer?

- What are the advantages of aluminum veneer?

- What are the special points to pay attention to when installing aluminum veneer?

- What is the production process of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Process and technological innovation of door roller coated aluminum veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: 2022-03-10 08:23:07

- Click:0

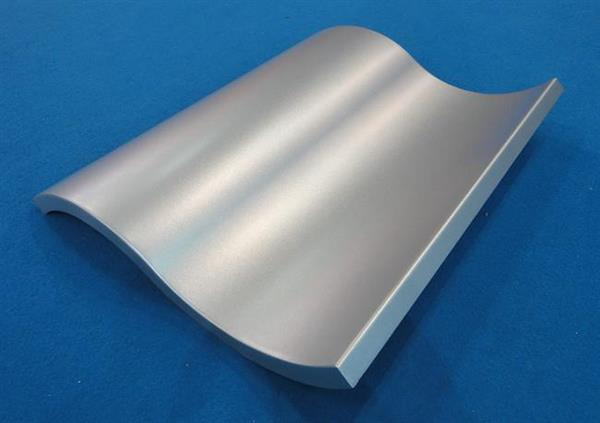

Door roller coated aluminum veneer is a very popular decorative material, which has the advantages of beauty, durability, and easy installation. It is widely used in commercial buildings, residential buildings, public facilities, and other fields. With the continuous development and innovation of technology, the process of coating aluminum veneer on door rollers is also constantly improving and perfecting. The following is a detailed introduction to the process and technological innovation of door roller coated aluminum veneer.

1. Pre treatment process

The surface quality of the aluminum veneer coated on the door roller has a crucial impact on its decorative effect. Pre treatment processes are required during the production process to ensure optimal surface quality. The pretreatment process mainly includes steps such as cleaning, degreasing, degreasing, and acid washing. These steps can effectively remove surface dirt and grease, improve surface smoothness and flatness, and provide a good foundation for subsequent spraying and painting.

1. Spray coating process

The spraying process is one of the key steps in the production of aluminum veneer coated with door rollers. The traditional spraying process adopts manual spraying, which is inefficient and prone to problems such as missed spraying and paint dripping. With the development of technology, automated spraying equipment is gradually being applied in the production of aluminum veneer coated with door rollers. Automated spraying equipment can achieve high-speed, efficient, and high-precision spraying, greatly improving production efficiency and product quality.

1. Painting process

The painting process is another key link in the production of aluminum veneer coated with door rollers. The traditional painting process adopts manual painting, which is inefficient and prone to problems such as color difference and uneven coating. With the development of technology, automated coating equipment is gradually being applied in the production of aluminum veneer coated with door rollers. Automated painting equipment can achieve high-speed, efficient, and high-precision painting, greatly improving production efficiency and product quality.

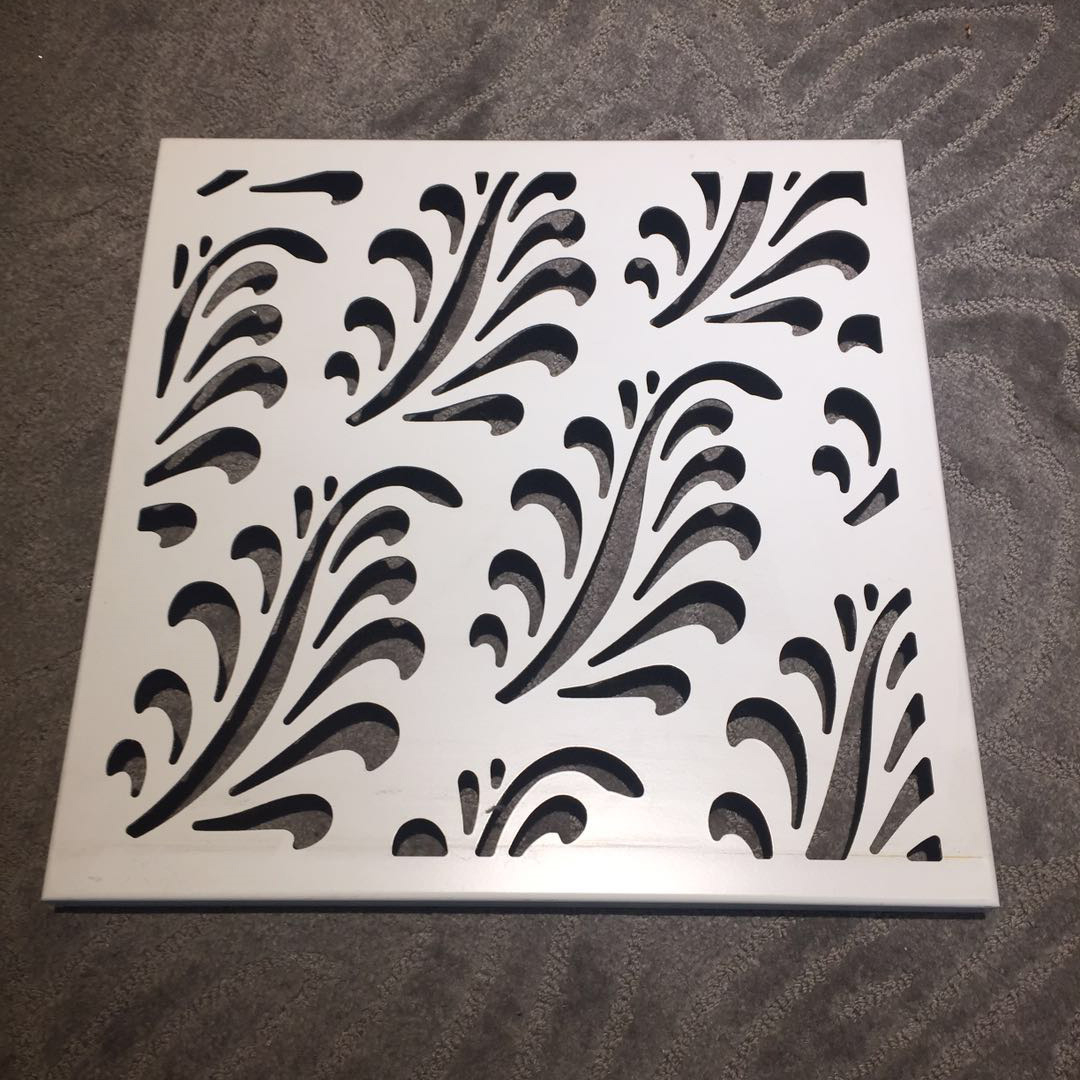

1. Innovative technology

In addition to the traditional processes mentioned above, the production of aluminum veneer coated with door rollers also adopts some innovative technologies, such as laser cutting technology, CNC machine tool technology, intelligent control systems, etc. The application of these technologies can further improve production efficiency and product quality, reduce production costs, and bring more competitive advantages to enterprises.

The process and technological innovation of coating aluminum veneer on door rollers play an important role in improving its quality and decorative effect. Through continuous improvement and refinement of production processes and technical means, the aluminum veneer coated on the door roller can be made more beautiful, durable, and easy to install, meeting the needs and expectations of different customers.

Customer service QQ

Customer service QQ