Industry information

Company News

- How much do you know about aluminum veneer: a green choice for modern architecture?

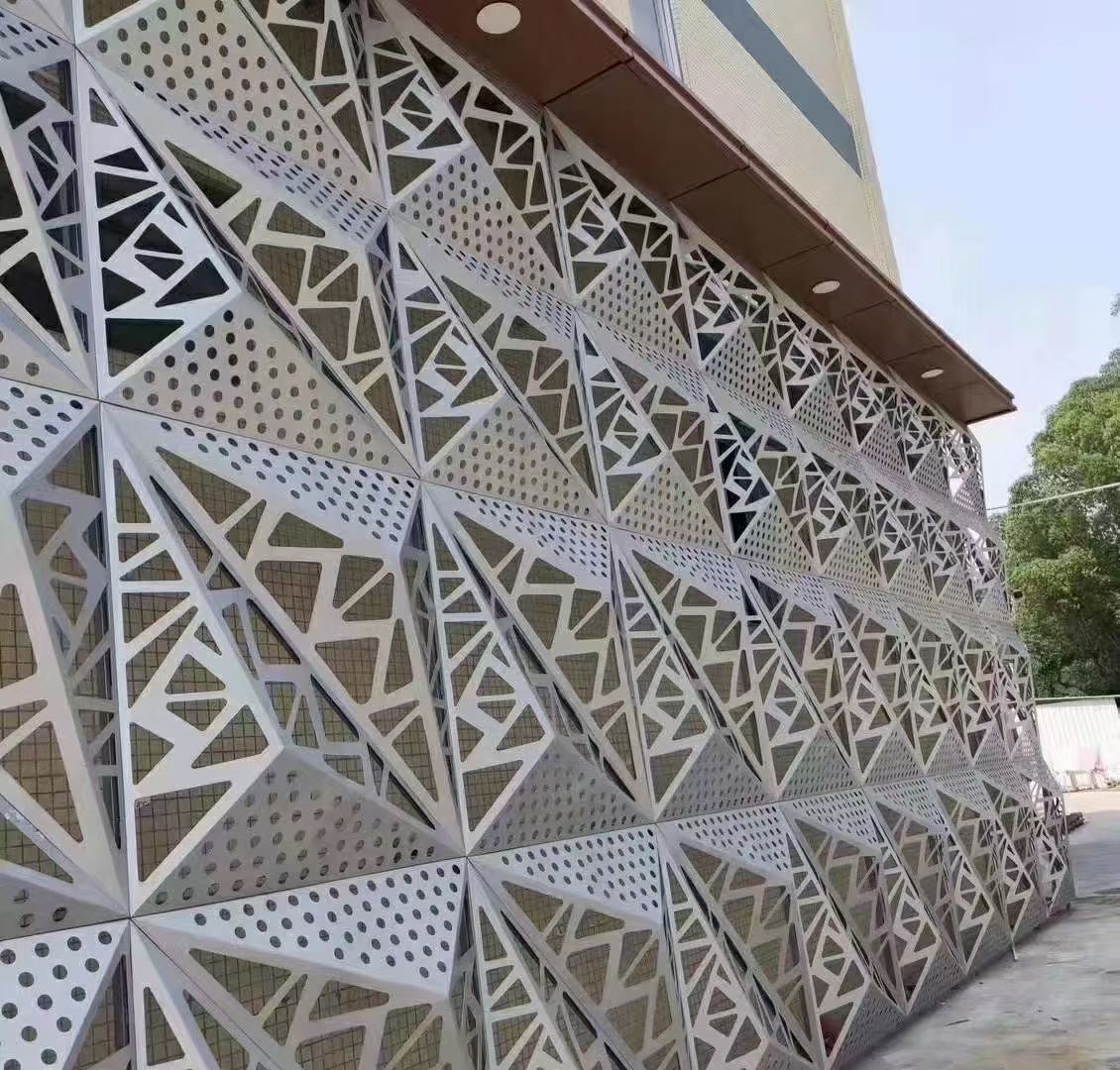

- Explore the unique charm of irregular aluminum veneer

- Hyperbolic aluminum veneer: the fashionable choice for modern architecture?

- The charm of aluminum veneer: the new darling of modern architecture

- Aluminum veneer: the fashionable new darling of the construction industry

Industry dynamics

- Aluminum veneer design inspiration and creativity are infinite!

- Analysis of the production process of twisted painted aluminum veneer

- Analysis of the production process of hollow baking paint aluminum veneer

- Sustainable utilization of environmentally friendly material hollow 1.5mm aluminum veneer

- Truly achieve 1.5mm roller coated aluminum veneer material

Frequently asked questions

- What occasions is aluminum veneer suitable for?

- What is the production process of aluminum veneer?

- What is the development prospect of aluminum veneer?

- How to check the quality of aluminum veneer?

- How to choose and purchase aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to improve the quality of customized aluminum veneer?

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: March 11, 2025 21:02:01

- Click:0

Aluminum veneer customization is a personalized customization service based on customer needs and requirements. How to improve product quality and customer satisfaction is an important issue that enterprises need to pay attention to when customizing aluminum veneer. Below, we will provide a detailed introduction on how to improve the quality of customized aluminum veneer.

1、 Optimize material procurement

The materials used for customized aluminum veneer should be high-quality aluminum alloy materials that comply with national standards and industry regulations. When purchasing materials, it is necessary to conduct strict testing and inspection on each batch of materials to ensure that the quality and performance of the materials meet the requirements. At the same time, it is necessary to compare and analyze different types of aluminum veneers to select the most suitable product material. We can also establish long-term stable cooperative relationships with suppliers to obtain better procurement prices and service guarantees.

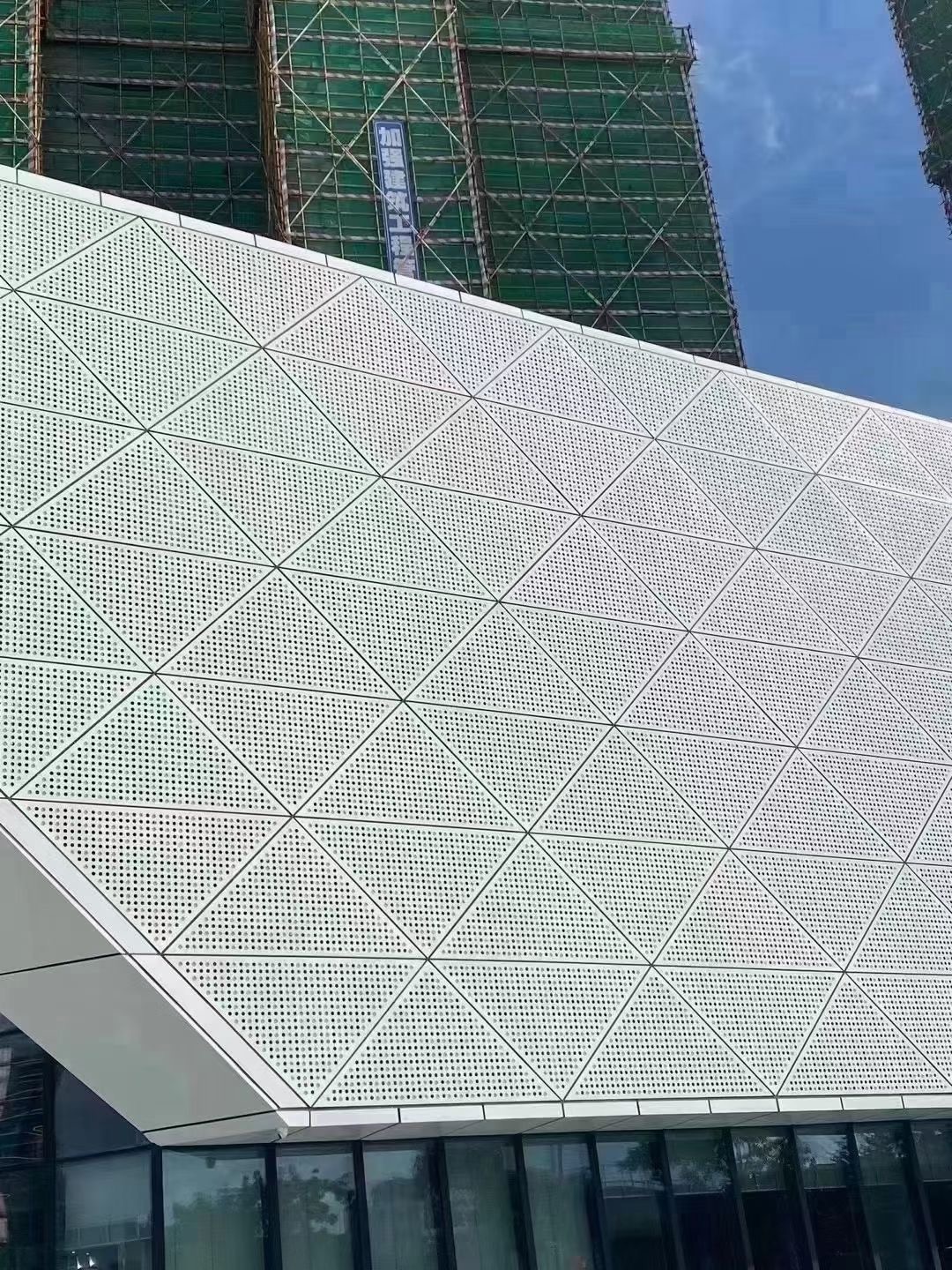

2、 Strengthen the quality control of processing

The customized processing process of aluminum veneer requires the use of advanced processing equipment and technology to ensure the accuracy and efficiency of the product. During the processing, attention should be paid to quality control and inspection at various stages, such as cutting, bending, punching, etc., to ensure the dimensional accuracy and surface smoothness of the product. At the same time, regular maintenance and upkeep of processing equipment are required to ensure its normal operation and production efficiency. We can also strengthen the training and management of employees, improve their technical level and work quality, thereby enhancing the quality and production efficiency of products.

3、 Optimize surface treatment process

The surface treatment of customized aluminum veneer requires multiple processes, such as anodizing, electrophoretic coating, etc. In the surface treatment process, it is necessary to strictly control the quality of each link, such as coating thickness, adhesion, color uniformity, etc., to ensure the appearance and durability of the product. We can continuously explore and develop new surface treatment processes and technologies to meet the needs and requirements of different customers.

4、 Strengthen packaging and transportation management

The packaging and transportation of customized aluminum veneer need to comply with national standards and industry regulations to ensure that the product is not damaged or deformed during transportation. Suitable packaging materials and methods need to be selected during the packaging process, and strict packaging labeling and marking should be carried out to prevent accidental disassembly and misuse. At the same time, it is necessary to conduct quality inspection and testing on the packaged aluminum veneer to ensure that the product meets quality standards and customer requirements. We can also strengthen the management and supervision of logistics companies to ensure that products can be delivered to customers on time.

5、 Continuous improvement and innovation

Improving the quality of customized aluminum veneer requires a spirit of continuous improvement and innovation. Enterprises should strengthen their research and analysis of the market and customers, understand their needs and requirements, and adjust product design and production processes in a timely manner. At the same time, it can also strengthen exchanges and cooperation with other fields, introduce new technologies and materials, and promote the innovative development of the aluminum veneer customization industry.

6、 Conclusion and Prospect

Through the introduction of how to improve the quality of customized aluminum veneer, it can be seen that improving the quality of customized aluminum veneer requires starting from multiple aspects, including optimizing material procurement, strengthening processing quality control, optimizing surface treatment processes, and strengthening packaging and transportation management. In the future, with the continuous advancement of technology and changes in market demand, the aluminum veneer industry will pay more attention to the improvement of product quality and service level to meet the needs and expectations of consumers. At the same time, it is necessary to strengthen communication and cooperation with other fields to provide consumers with more comprehensive and objective selection criteria and service support. For enterprises, they should strengthen research and development innovation and technological upgrading, improve product quality and service level, in order to enhance their competitiveness and profitability. At the same time, it is necessary to strengthen cooperation and communication with other brands to jointly promote the development of the entire aluminum veneer industry.

Customer service QQ

Customer service QQ