Industry information

Company News

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Aluminum veneer: the beauty of architecture, simplicity is not simple

- Aluminum veneer decoration is a new trend, with both material aesthetics and aesthetics!

- The secret behind aluminum veneer: the story behind lightness

- Unveiling the 'magnificent transformation' of curtain wall aluminum veneer

Industry dynamics

- Material characteristics and selection guide of perforated aluminum veneer for ceiling

- The beauty of the transformation of aluminum veneer curtain walls separated by a board

- Explore the unique charm of irregular aluminum veneer

- Hyperbolic aluminum veneer: a fashionable new favorite for creating modern architecture

- Customized aluminum veneer, creating personalized space and new fashion

Frequently asked questions

- What is the production process of aluminum veneer?

- What are the surface treatment methods for aluminum veneer?

- What are the special points to pay attention to when installing aluminum veneer?

- What is the approximate price of aluminum veneer?

- What are the advantages of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

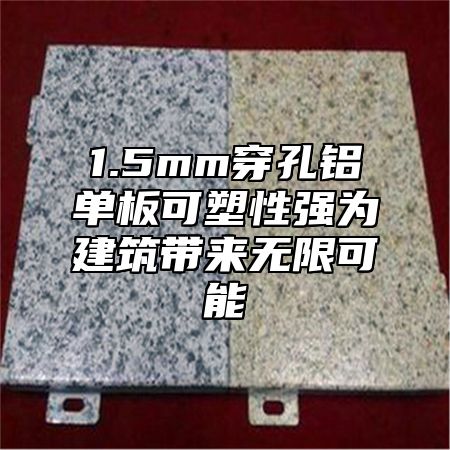

1.5mm perforated aluminum veneer with strong plasticity brings infinite possibilities to buildings

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: 2022-03-10 20:36:13

- Click:0

As an innovative building material, 1.5mm perforated aluminum veneer has strong plasticity and can be customized according to different design requirements, bringing infinite possibilities to buildings. This article will provide a detailed introduction to how 1.5mm perforated aluminum veneer can change the appearance of buildings through its plasticity from multiple perspectives.

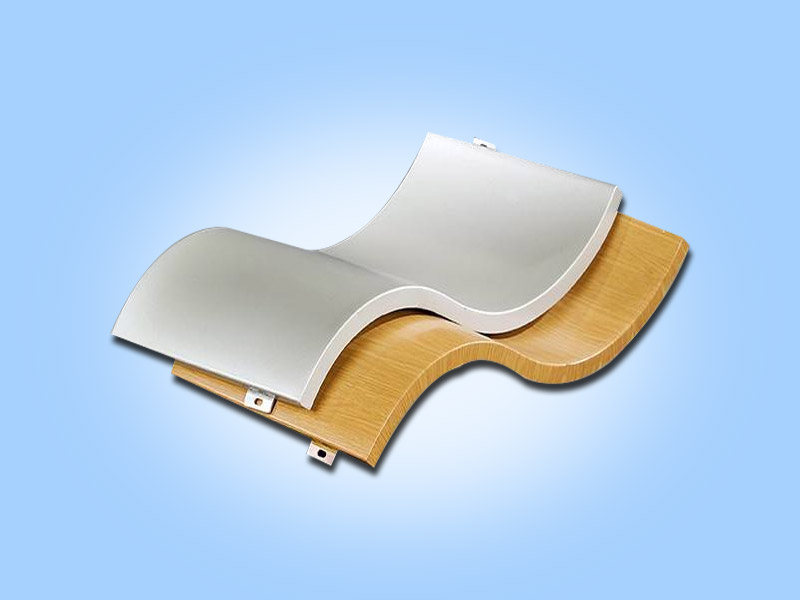

1、 Diversified design styles

1.5mm perforated aluminum veneer can be customized according to different design requirements, showcasing diverse design styles. For example, a modern minimalist style can be adopted, with simple lines and large areas of white as the main color tone, creating a refreshing and bright sense of space; European classical style can also be adopted, featuring exquisite carvings and reliefs to showcase a noble and elegant atmosphere. Personalized design can also be carried out according to the needs of customers to meet their different requirements.

2、 Innovative punching design

In addition to its rich design style, 1.5mm perforated aluminum veneer also features innovative punching design. Punching is a technique of creating patterns or text by punching holes in aluminum plates through machines or manual labor. Aluminum veneer manufacturers can customize punching designs according to customer needs, creating unique decorative effects. For example, company logos or product names can be punched on aluminum veneers to enhance brand image and product recognition; Various patterns and designs can also be punched out to enhance decorative effects and artistic value.

3、 Application areas with strong plasticity

1.5mm perforated aluminum veneer can not only be used for indoor decoration, but also widely applied in outdoor construction, transportation, electronic products and other fields. For example, using 1.5mm perforated aluminum panels in urban public facilities can beautify the urban environment and enhance the city's image; The use of 1.5mm perforated aluminum veneer in automobile manufacturing can improve the safety and comfort of the vehicle body; The use of 1.5mm perforated aluminum veneer in electronic products can improve the product's heat dissipation and durability.

4、 Design concept of environmental protection and energy conservation

The 1.5mm perforated aluminum veneer can also reflect the design concept of environmental protection and energy conservation. Aluminum veneer manufacturers can choose to use environmentally friendly materials and production processes to reduce their impact on the environment; Energy saving factors can also be considered in the design, such as using double-layer insulated glass curtain walls to reduce the building's energy consumption and carbon emissions. These environmentally friendly and energy-saving design concepts can not only increase the added value and social responsibility of products, but also meet customers' needs for environmental protection and energy conservation.

5、 Conclusion

1.5mm perforated aluminum veneer, with its strong plasticity, can be customized according to different design requirements, bringing infinite possibilities to buildings. Aluminum veneer manufacturers should focus on product design innovation and service level improvement to meet the different needs and expectations of customers. Only in this way can we stand invincible in the fierce market competition and achieve long-term stable development.

Customer service QQ

Customer service QQ