Industry information

Company News

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Aluminum veneer: the new darling of industrial aesthetics

- Aluminum veneer customization, creating personalized space and new fashion

- Aluminum veneer, the hidden protagonist in modern architecture

- Fluorocarbon aluminum veneer: the fashionable choice for modern architecture?

Industry dynamics

- Unveiling Irregular Aluminum Veneers: Fashion Experts in the Aluminum Industry

- Installation method of wood grain hyperbolic aluminum veneer

- Hyperbolic aluminum veneer: a new trend in aluminum materials and a new landscape in architecture

- Come and take a look! What's the secret behind the quotation for aluminum veneer that will leave you amazed!

- Aluminum veneer: the fashionable outerwear of modern architecture

Frequently asked questions

- What are the surface treatment methods for aluminum veneer?

- What is the production process of aluminum veneer?

- What environmental issues should be paid attention to in the production and use of aluminum veneer?

- What are the special points to pay attention to when installing aluminum veneer?

- What occasions is aluminum veneer suitable for?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

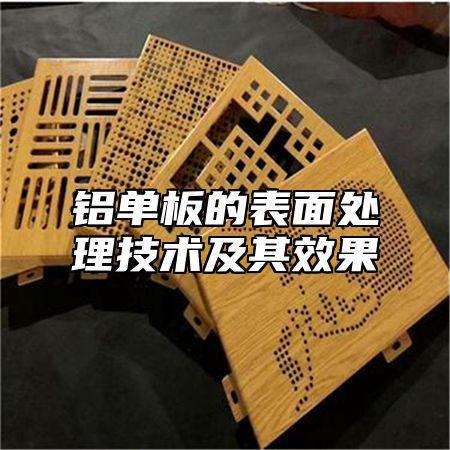

Surface treatment technology and its effects on aluminum veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: 2022-03-05 11:27:39

- Click:0

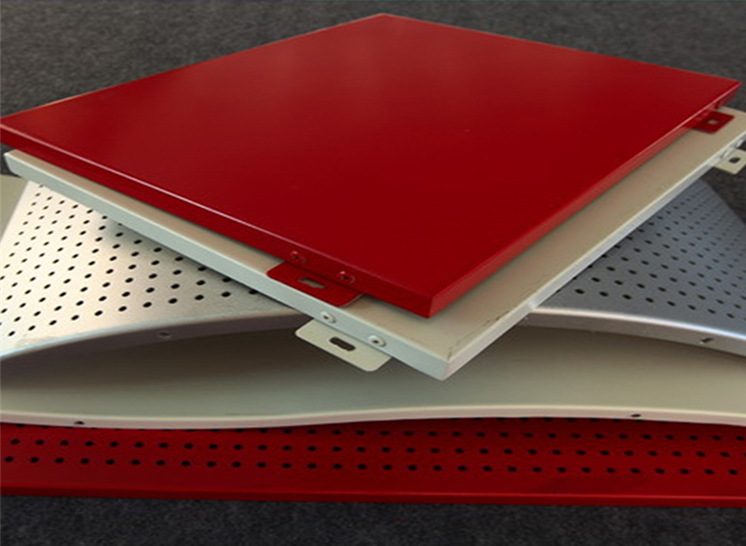

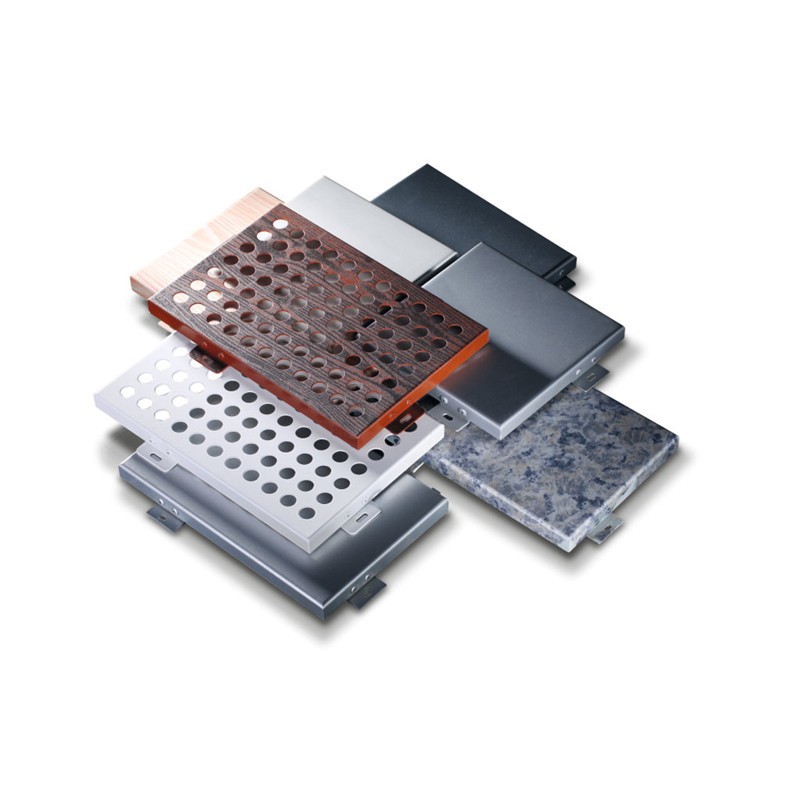

As a new type of building material, the surface treatment technology of aluminum veneer has a significant impact on its application effect. The common surface treatment techniques for aluminum veneer mainly include anodizing, fluorocarbon spraying, etc. Below, we will provide a detailed introduction to the surface treatment technology and its effects on aluminum veneer.

Anodizing is a commonly used surface treatment technique for aluminum veneer. By anodizing the surface of aluminum veneer, a dense oxide film can be formed, thereby improving the wear resistance, corrosion resistance, and aesthetics of the aluminum veneer. Anodizing can also change the color and texture of aluminum veneer, giving it a better decorative effect.

Fluorocarbon spraying is another commonly used surface treatment technique for aluminum veneer. By applying fluorocarbon spray treatment on the surface of aluminum veneer, a coating with good weather resistance and UV resistance can be formed, thereby improving the service life and aesthetics of the aluminum veneer. Fluorocarbon spraying can also create different colors and textures, giving it a better decorative effect.

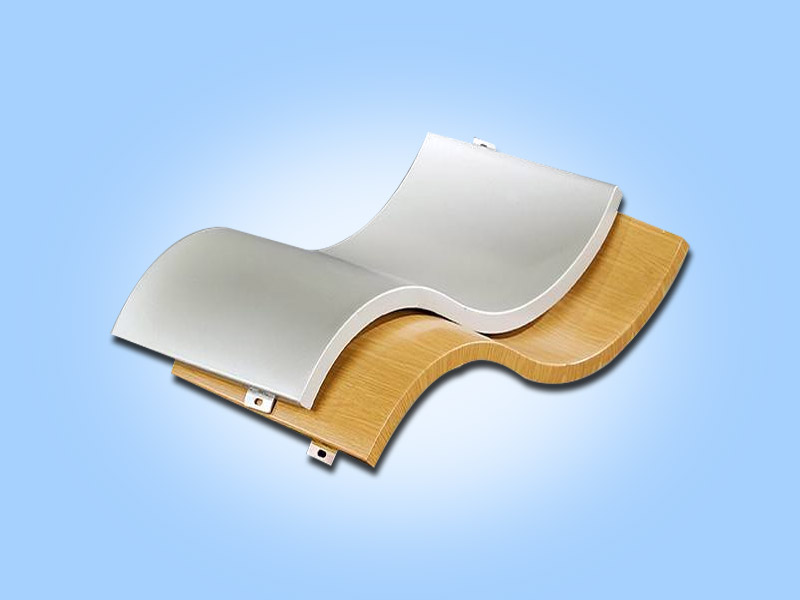

In addition to the above two surface treatment techniques, there are other surface treatment techniques to choose from, such as electrophoretic coating, heat transfer printing, etc. These surface treatment techniques each have their own advantages and disadvantages, and need to be selected according to the actual situation.

The surface treatment technology of aluminum veneer has a significant impact on its application effect. By continuously innovating and applying new technologies to enhance product quality and service levels, the market competitiveness and market share of aluminum veneer can be further improved, achieving maximum investment return. Both investors and production enterprises need to closely monitor the new technologies and trends in the aluminum veneer industry, adjust their business strategies and investment directions in a timely manner, in order to seize market opportunities.

Customer service QQ

Customer service QQ